First a prelude to getting on the water. Covid 19 has had an affect on everyone’s lives in terms of freedoms, plans, health, work, relationships. It has very much been a gamechanger. For many this meant no more holidays for a while, very limited socialising, lack of ability to enjoy public spaces and so much more. It would seem that many have decided to explore those things they always fancied doing, to stop putting things off because you truly never know what is around the corner. The indiscriminate manner in which Covid exploded into our lives is a stark reminder of this.

For us as a family of four and a doggy, it has been no different and has certainly spurred us into considering an escape to the water a lot sooner than we would have anticipated otherwise. Both myself and my wife were fortunate to have grown up around boats. My Grandfather owned a little Sunseeker Daycab 23 sport cruiser which I used to accompany him and help him with all the time, and my wife’s father always had fishing boats.

This gave us enough insight to appreciate how much work they can be and the level of commitment and dedication it requires. Unlike most other vehicles, you can’t just park a boat up throw a cover over it and forget about it (unless it’s a trailer boat!!), it needs feeding all the time, mooring fees, insurance, anti foul, anodes regardless of use or lack of. However you never truly realise the full extent of it when you’re merely perusing glossy adverts from the side-lines.

The search is on…

Our search started fairly modestly, looking at trailer boats or a river boat kept on a river mooring. After much reading we decided against a trailer boat, research taught us that those weekend days when the weather is good, every one will be heading to the slipways with the same idea, with the likelihood of queuing for ages! We strongly considered a Shetland 4+2 to keep at our local river but the thought of only going up and down the same patch each time felt like the novelty may soon wear off. We looked at lots of adverts, combined with research of all sorts every evening, reading as many noob forum posts and the advice dished out by seasoned boaters as much as possible. I even posted a couple of topics of my own.

Contender Number 1

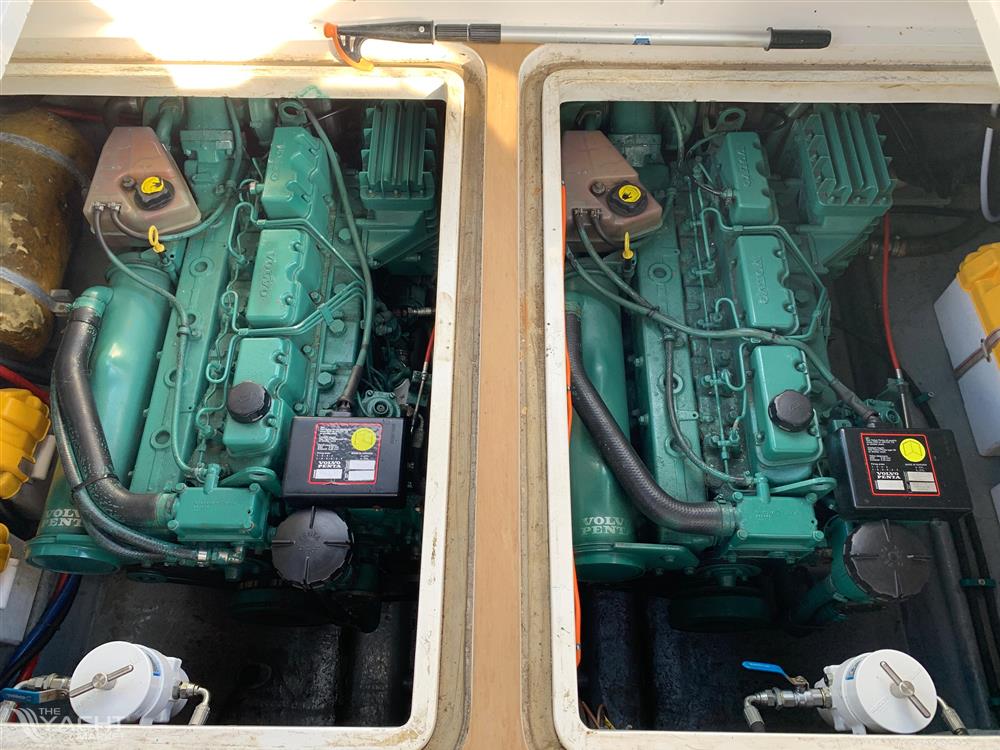

As the search continued my interest is piqued by an advert that has captured my imagination, after which there is no turning back. A 1985 Sunseeker San Remo 33 with twin inboard Volvo Penta AD41 200hp engines on outdrives, a beautiful little example with much recent and high quality work carried out.

I first saw it on ebay and started conversing with the owner to get an idea of running costs and fuel consumption. If we are going to get a boat, it was going to have to be a Sunseeker!

The reasoning for this is thus; If I’m going to be putting this amount of time and effort into something, it simply has to be something that my heart is into. The juice has to be worth the squeeze and for me, I had never really thought that I would seriously ever get a boat, but there is only one brand of boat that has always and consistently appealed to me, possibly from a culmination of my idolisation of my Grandfather and an early indoctrination into the brand followed by a trip out on a relatives beautiful Sunseeker Travado in the 80’s which seemed like something from Miami Vice compared to my Grandfather’s one not to mention of course all the Bond movies that featured them over the years. This would mean upping the budget which meant that the flash car (which was only covering about 2500 miles a year) had to go.

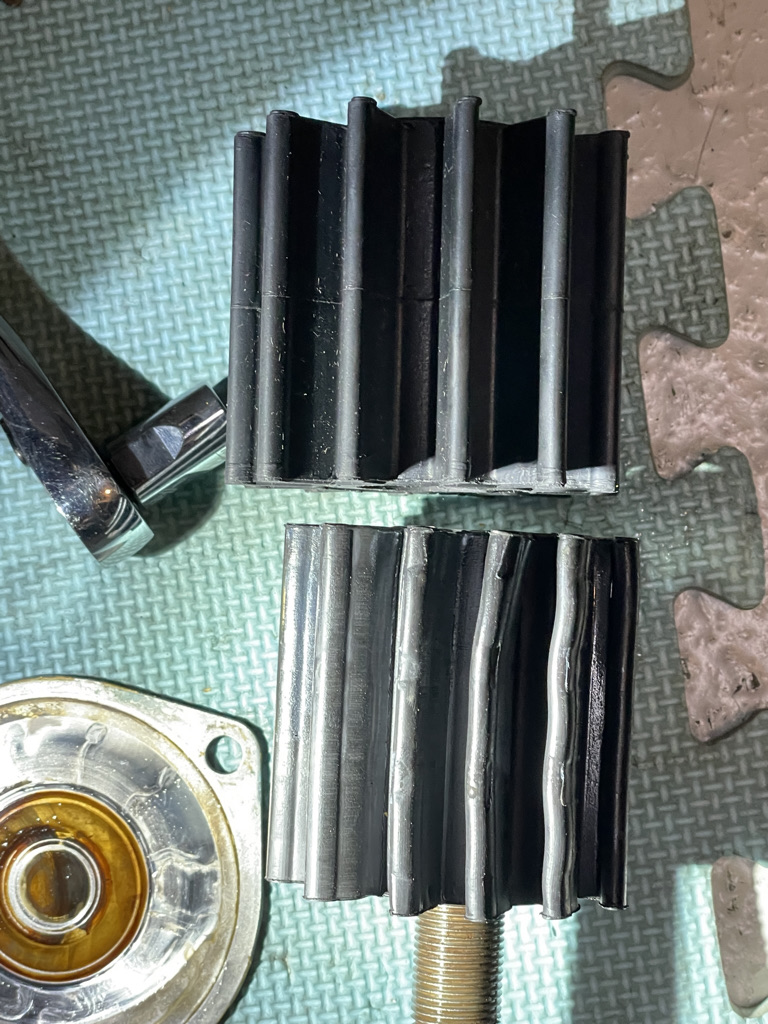

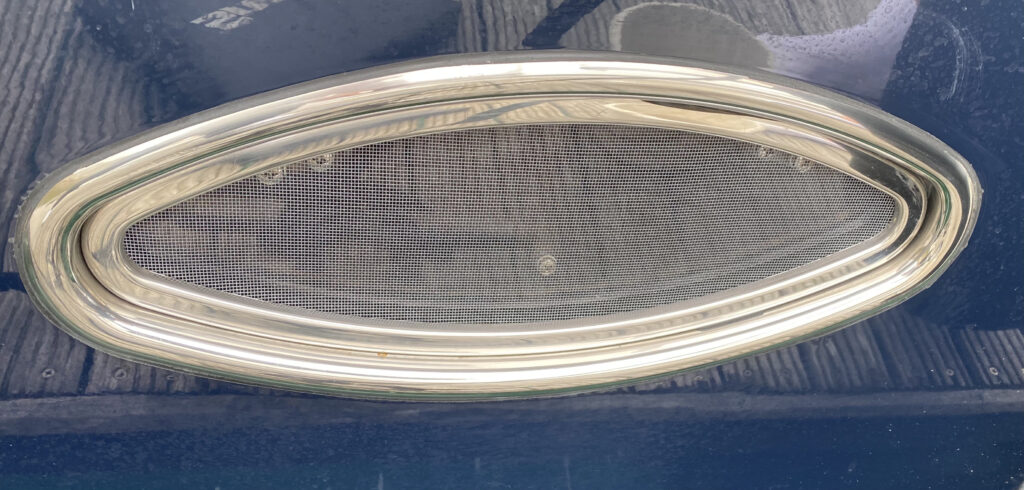

I’m gradually getting drawn in more and more, this leads to both wider and more focused research where all sorts of things to look out for start coming out of the woodwork …Osmosis….Outdrives….I’m downloading engine and outdrive manuals, reading up all about osmosis, transom shields, bellows, skin fittings, sea cocks, anything below the waterline, rotten bulkheads etc etc. My head is literally exploding, but we continue somewhat undeterred but perhaps allowing for a certain amount of leeway or forgiveness toward the right boat. I’ve fallen in love with this one, it’s the first boat that we we go to look at, the only downside is what appears to be osmosis coming through its copper coated hull. After thoroughly researching and putting in my mind that it’s going to take some time to tackle the issue, we talk the price down considerably. Once we’re almost there, we then find out through the grapevine that a previous potential buyers surveyors report had picked up a rotted section of the main bulkhead between the engines and rear cabin. We adjust the offer accordingly, but we’re a couple of grand adrift. I just can’t forgive any more issues, it’s already becoming too much, it wasn’t a project boat that we set out to buy and the costs and time it would incur to bring the boat to the same standard that the rest of it was prepared to were already starting to stack up. So we had to say goodbye to number 1 which was a shame because I’d fallen for that one. We then looked at a couple of Martinique 36 footers, these gave some pause for thought but neither were at the high standard of maintenance that we were targeting, we even looked the other way at a local Riva 38 Special, ironically it was snapped up by the folks who originally had the San Remo 33 surveyed.

Contender number 2

Along comes number 2 of the serious contenders, a Martinique 39 in the Netherlands (we’re up to 39 foot now)!

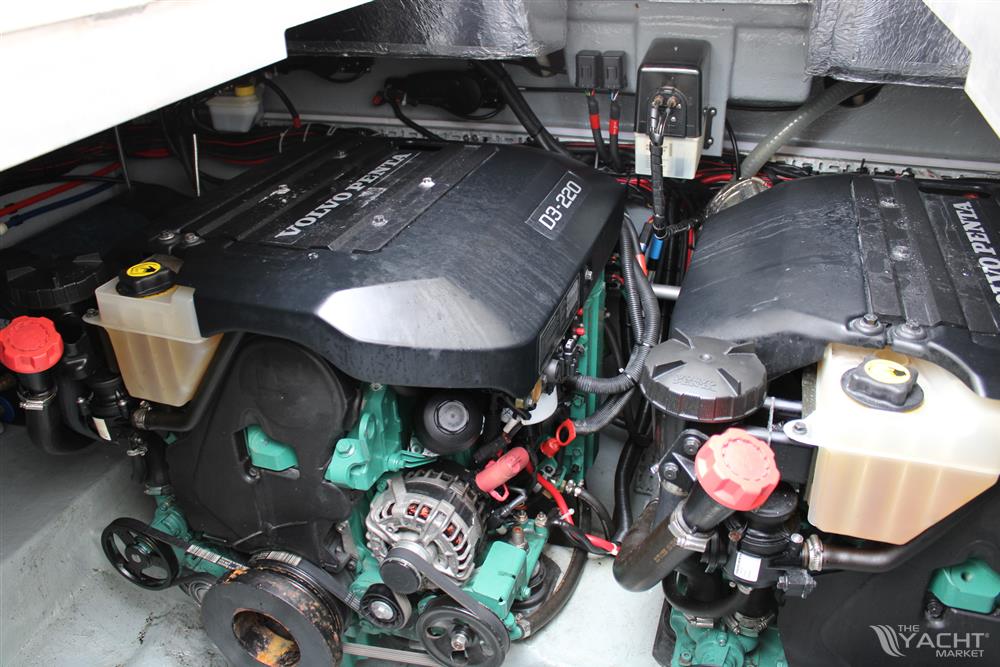

The boat has recently had more than the asking price spent on it, it has been repowered with new Volvo D3 engines (220hp each).

Lots of pictures and dialogue later, we’re nearly at a deal, offers have been discussed and we are getting towards an acceptable figure for both sides…

but it sells the very day before we make our formal offer. To our frustration, some 3 months later the deal still isn’t concluded and Brexit has since happened, making this unfeasible even if it did fall through, however it doesn’t. Forumites tell me this is a blessing in disguise. The D3 engines are slated by so many, although I had read this before there were also benefits, although they are lightweight aluminium car derived blocks, they represent a huge weight saving, they are quiet, efficient and easy to get around to work on since they are so small. Still, some scathing forum posts follow about them which helps me to move on from this one. We have been looking since June 2020 and we’re now at the beginning of 2021. We briefly consider a Mustique 42 on shafts and even a Camargue 46, but after much research on the noisy and thirsty Detroit 2 stroke diesels again I feel along with their increased length that we would be getting far to carried away for a first boat. We consider a Portofino 375 that has been for sale for ages, then a nice 400, only the broker can’t produce any receipts for the repowered and mismatched Yamaha 420STi engines, but it sells virtually straight away anyway. Another Martinique 36 turns up, no good, a Martinique 38, again no good.

Contender number 3

Then out of nowhere, No.3 turns up purely by accident.

It’s another Martinique 39, only this time, it’s powered by a pair of very nice Yamaha 420 STi 240hp each engines.

These are the same 4.2L engine fitted to the Toyota Landcruiser of which we have experience…perhaps this is meant to be. We have the idyllic viewing, the weather is beautiful, and we get taken out to sea on it across Studland Bay. This is the best sales technique of all. The engines are quiet, refined, there is decent speed and power, the party cabin can accommodate 10 easily the whole thing just feels right and it’s a decent price leaving us with funds to play with.

My wife is smiling away. It needs some minor bits of attention, but a very long ownership spell with all the receipts bodes well. We go away and make an offer and it’s accepted. The dream may be turning into a reality. Only upon arranging the survey the seller gets cold feet and pulls out. He can’t find a replacement and doesn’t want to be boatless for the season.

Just how hard can it be to buy a boat? It’s getting almost depressing at this stage, we have driven around the country, we’ve been trawling adverts, engaged with sellers and brokers, spoken to workshops and specialists, surveyors, I’ve read up on all sorts of engines, having swotted up on VP AD41’s, VP D3’s,Yamaha 420STi’s, different outdrives, Detroit Diesels and shaft drives and we just can’t find anything. In the meantime the overheated market place means anything decent is selling immediately. As a cautious buyer, there is no time to make lengthy purchasing decisions and there will be no bargains for a nice boat.

Contender number 4

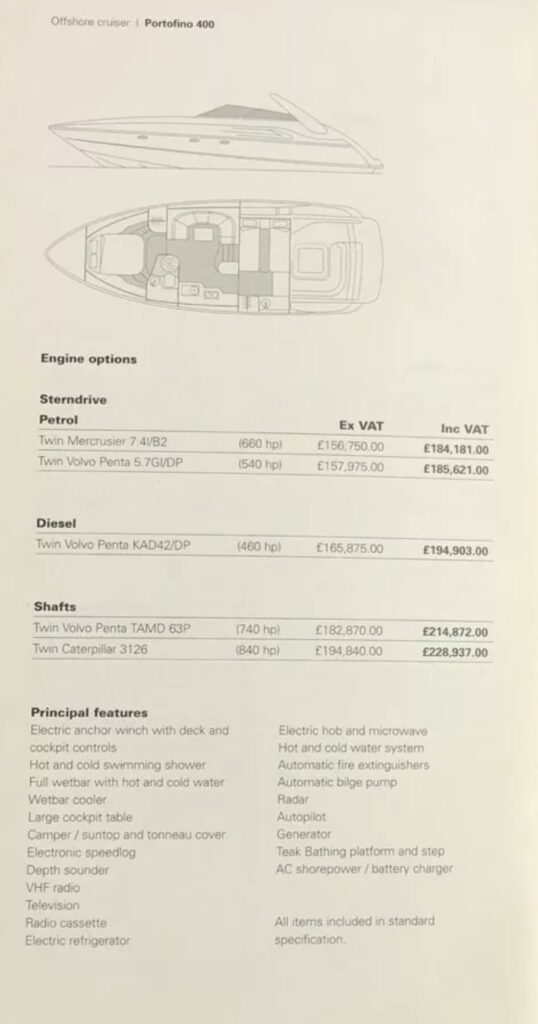

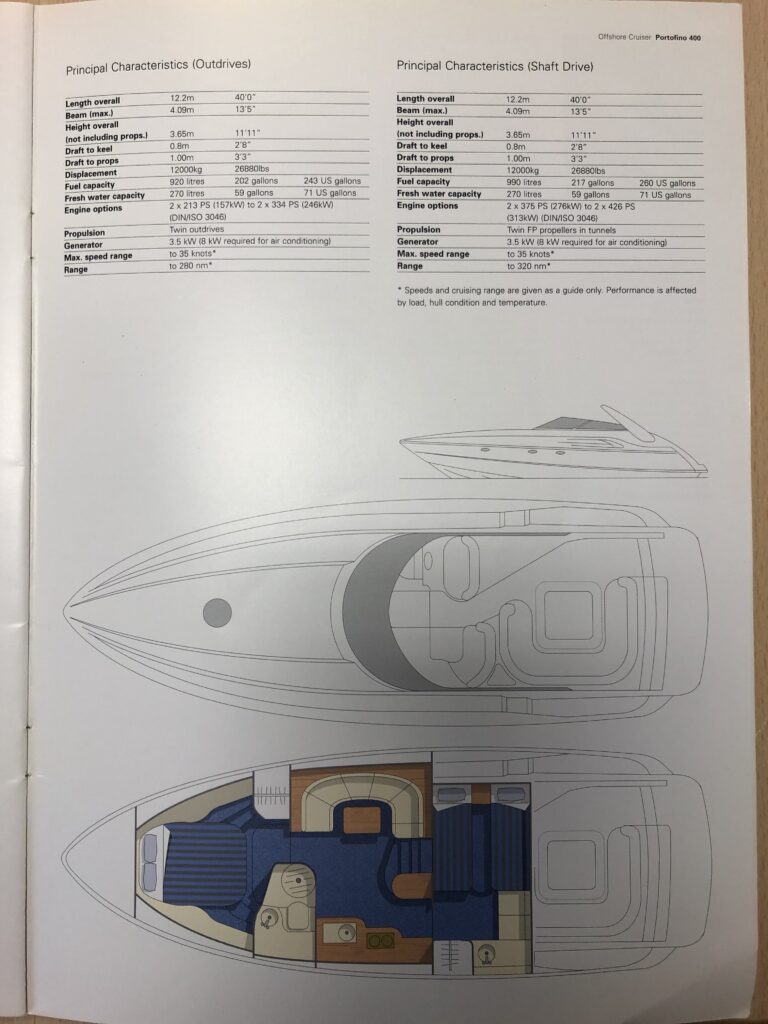

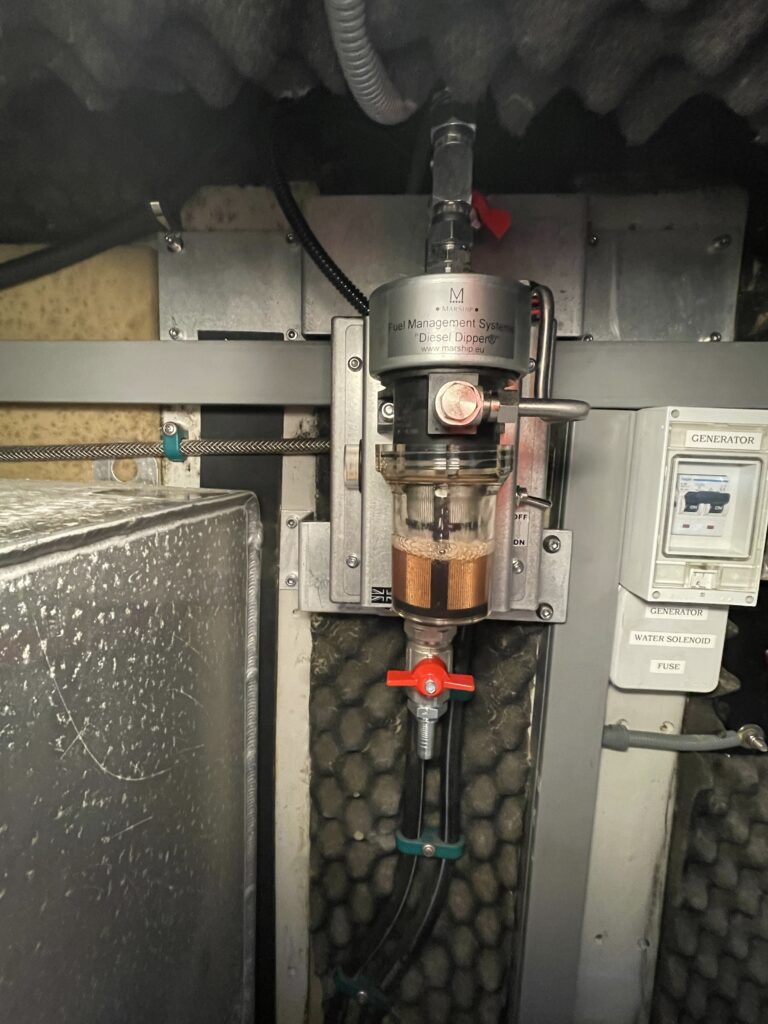

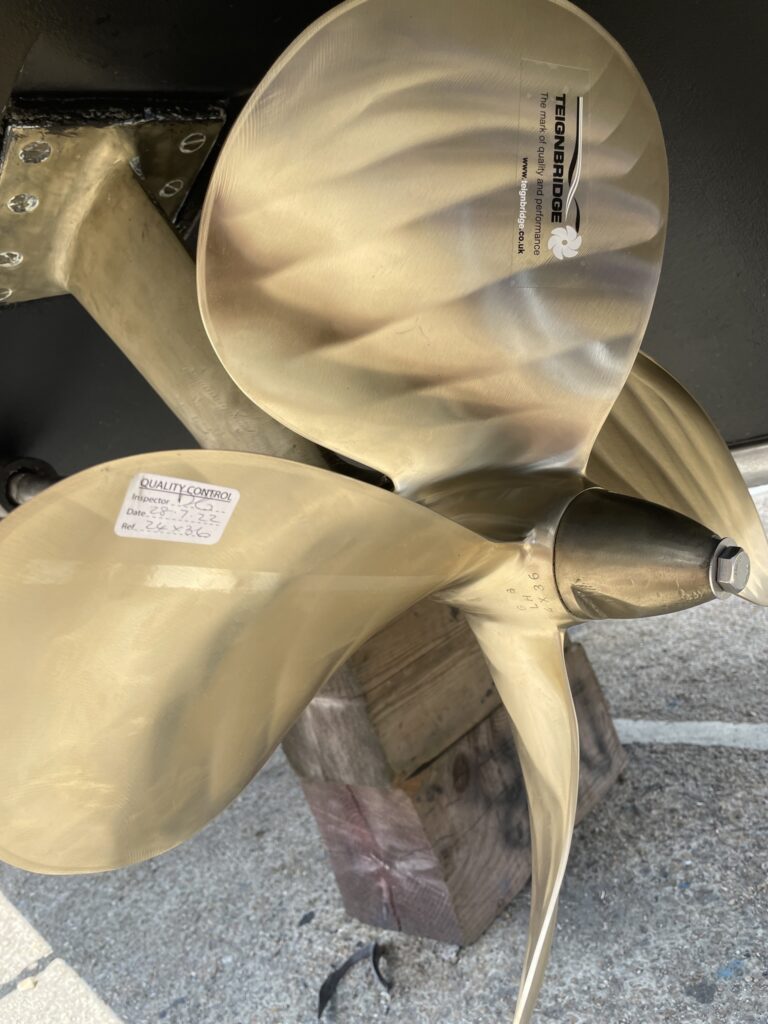

Then along comes No.4, a 1997 Sunseeker Portofino 400. These were available with either outdrives or shaft drives. This particular model is equipped with the higher specified and sought after shaft drive format.

The advert goes up, it looks stunning and my wife is on the phone to the broker immediately, it’s a lot dearer than the Martinique 39, and appears to have a horseshoe seating arrangement with a wetbar whereas the Martinique had seating all around.

I’m reluctant to traipse all the way back down to Poole to look at another boat particularly as the seating arrangement looks smaller than the Martinique but the wife wants to look at it, so of course we arrange to do this. At the same time I am searching the helpful YBW forum and I put 2 & 2 together and come across the owner on the forum, whom I private message. We get chatting about fuel consumption, boat history and other such likes, armed with the info he has provided I do a load of research on the engines as this throws yet another engine manufacturer into the mix! Heavy duty Caterpillars this time.

We are fortunate to be the first viewers, this is in a different league to everything else we have looked at and for the first time, it looks like a boat that is truly ready to go with seemingly no real spend required to bring it up to standard.

The boat is on the hard when we arrive and it looks immense!

It appears to have been very well looked after by its current owners with lots of recent spend from the last 5 years for updates and maintenace. My concerns over the lack of seating are misplaced, although it is only 1 foot longer than the Martinique, it is also 410mm wider, which may not sound a lot on paper, but in the GRP it is substantially beamier. Volumetrically, that extra foot and nearly half a metre additional beam makes for a massive party cockpit that will easily accommodate 10-12.

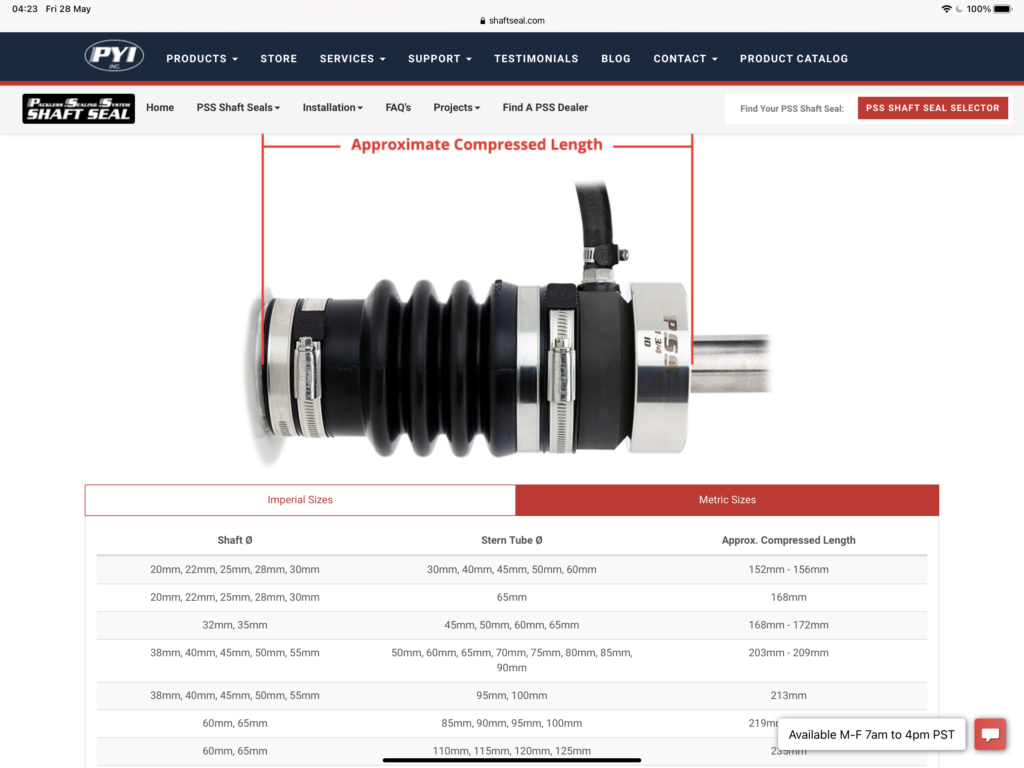

I like it very much, not least because I can see that it has been well looked after, which should make my job of maintaining it somewhat easier. There are concerns however. This is the first shaft boat we have viewed, although everyone keeps telling me to avoid outdrives, I had already done so much research on them that I had begun to feel comfortable with maintaining outdrives and I liked the efficiency and agility they afford. Would shafts make the boat a lumbering but well planted sloth? Apparently shafts are virtually maintenance free according to the owner so there are no long term concerns with that.

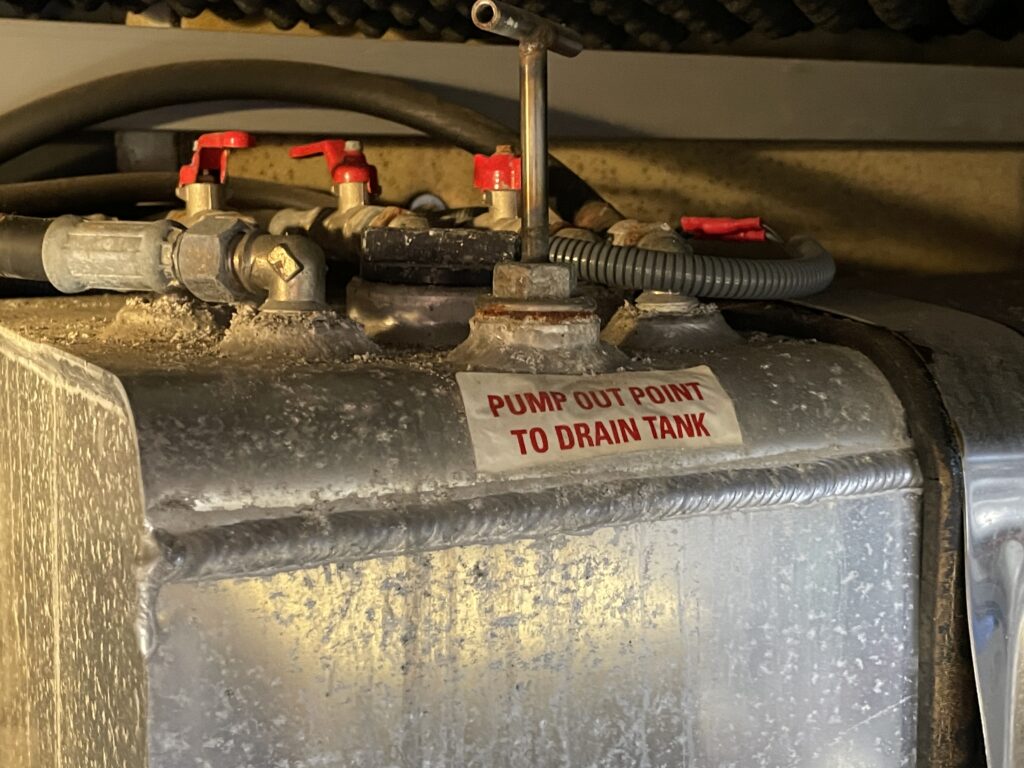

It’s the engines, powered by a pair of monster Caterpillar 3126’s with 420hp each has me panicking about fuel costs. The owner assures me his typical consumption is 70-80L an hour for the pair at cruise, which is similar to the initial and much smaller twin engined San Remo on outdrives which the owner advised was between 60-70L also at a 22 knot cruising speed. Although this seems scarcely believable given the size differential of the boats and the more than doubled power output of each engine. I find some supporting literature from Caterpillar and also read other owners experiences which reassures me as it seems to affirm what the owner has said which gives me some confidence.

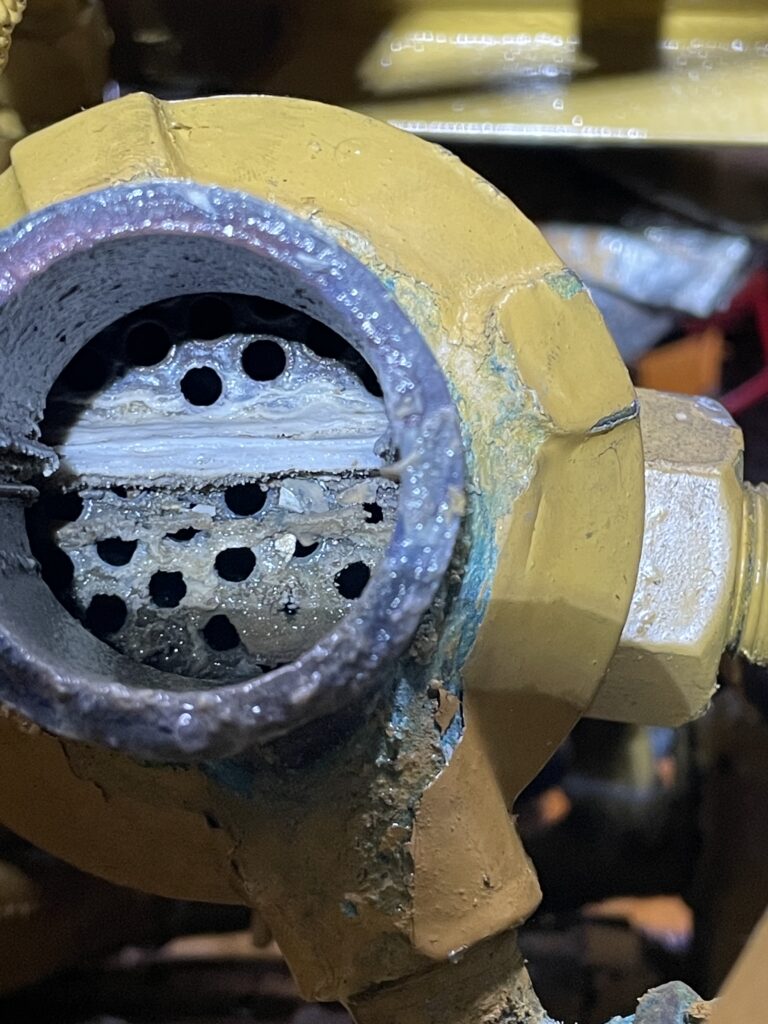

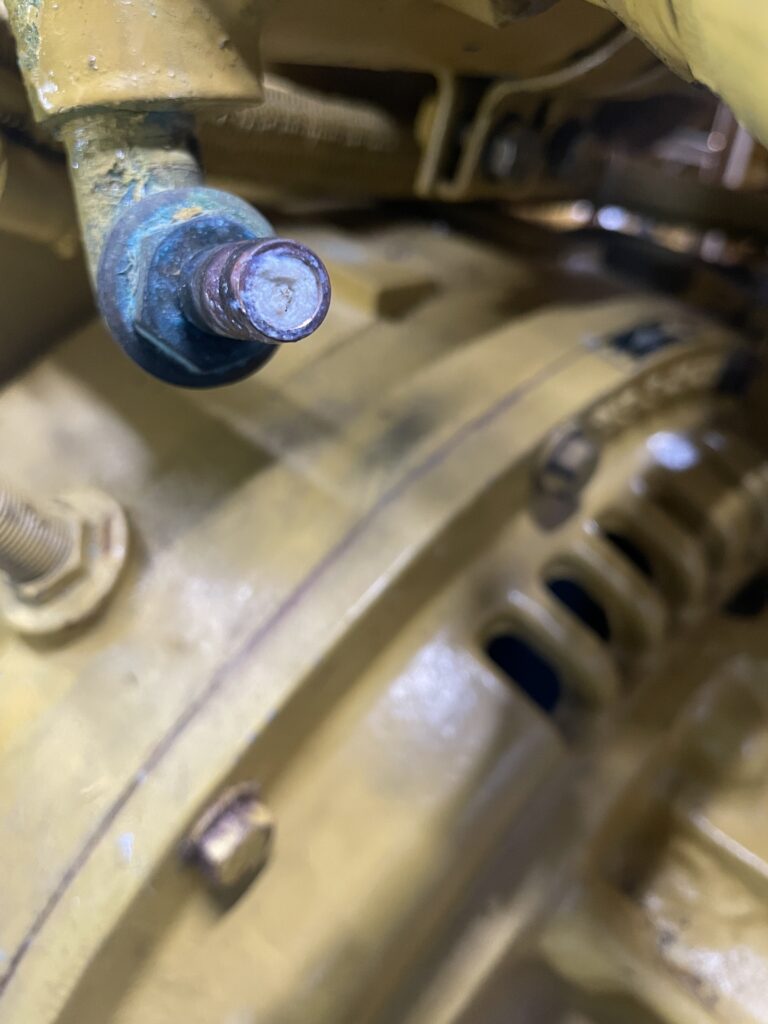

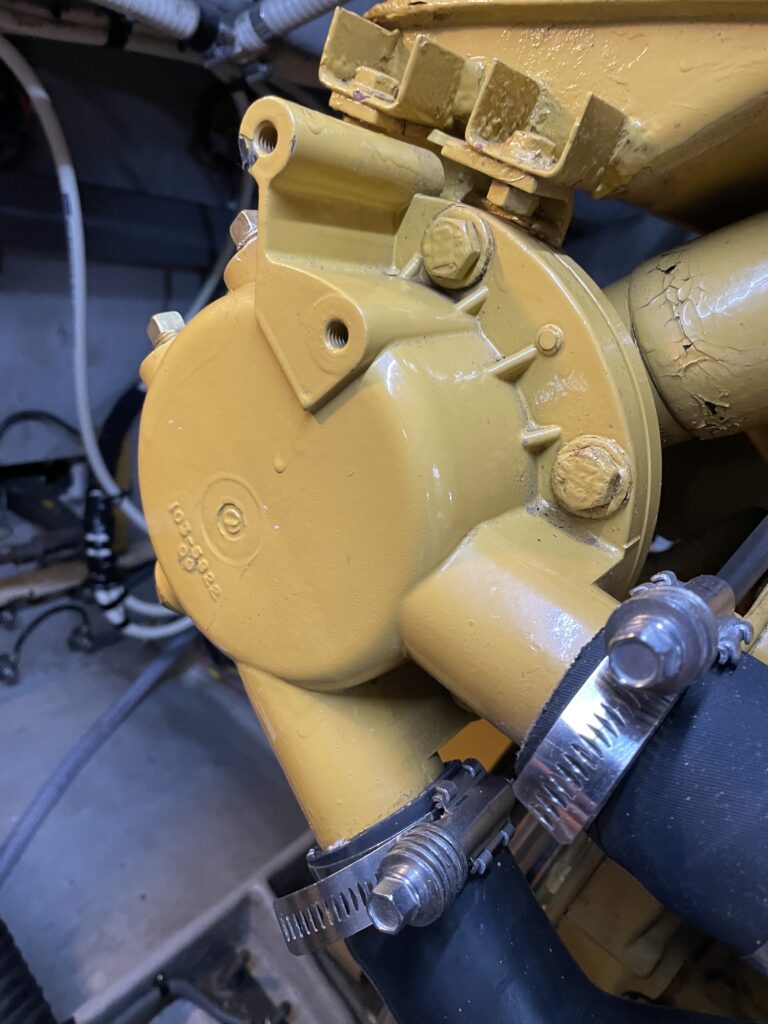

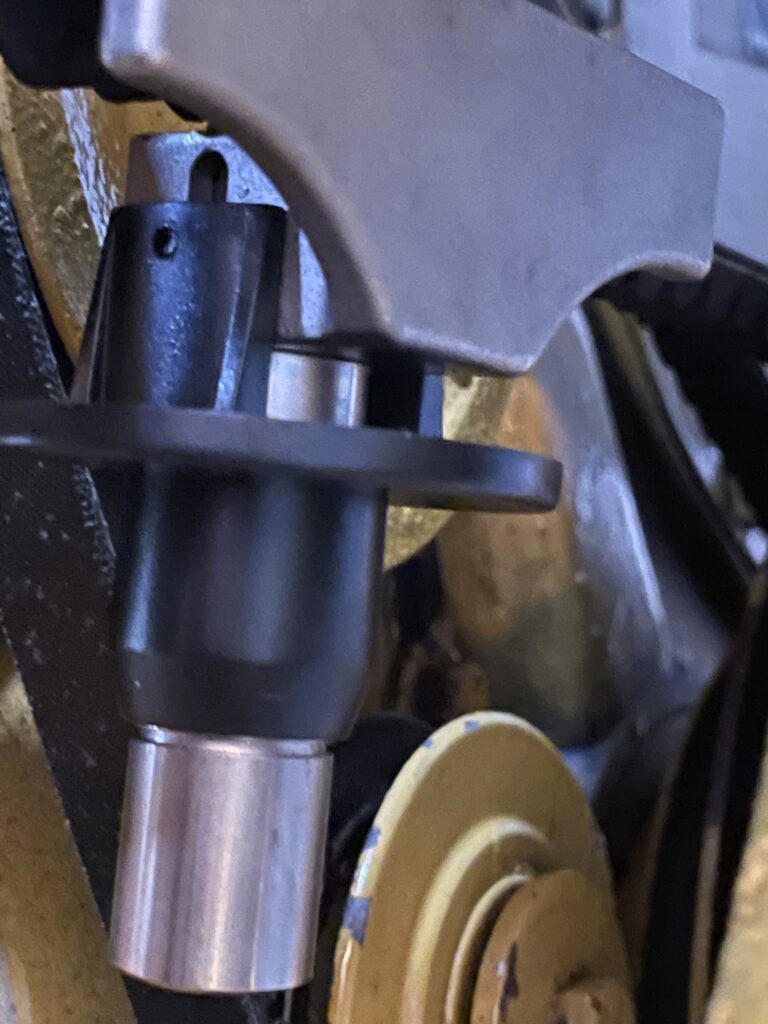

With a total of 840hp it is twice the power of the next boat we had viewed, it’s also the largest. The boat is equipped with a generator, air conditioning, hot water, a sophisticated battery management system with inverter, there is an awful lot to take in. Rather than an engine bay, this has an engine room, the first boat to view where you actually climb down via ladder into the engine’s compartment and they are huge! My wife quickly departs back to the car. I’m there for about 3 hours with the broker. She looks quite unimpressed, after a long chat we come to the conclusion that it isn’t that she doesn’t like it, rather that like me, she found the whole thing somewhat overwhelming. From the Martinique 39 that she loved, this was in size and budget a far departure from where we started. The budget and size of boat had been gradually growing and this seemed like another level of complexity along with the on costs of bigger moorings and so forth.

We go away and spend a couple of days discussing amongst ourselves, we’re undecided, it’s a big step, time isn’t on our side, we have learned that lesson, the boat is good, it feels like too serious a boat for us as a first foray into boat ownership, I have doubts about my ability to handle such a big boat, particularly as a first boat and to take on all the liabilities that come with it, it’s some way out of our comfort zone, but we’ve been searching for too long, in the end, I left it to fate, calling on a 10p coin on my desk, tails we go for it….(and on the first flip 😉 ) tails it is!!

We call up to make an offer, the Broker explains to me that it’s not that easy, the second viewers are also considering making an offer and he has to wait for them to come back. I suggest so what if we were to offer the full asking price? He tells me it doesn’t matter, the seller has to accept our offer. Ok, so now we wait with bated breath for the other viewers to come back as we can feel the next one slipping through our fingers. I decide to stick to our guns of what we feel it’s worth and put that in as a formal offer, it means we are disadvantaged by moving first because the other viewers could be played off against our figure. As it transpires, the other viewers can’t secure the financing. Having been viewing for almost a year, we are literally ready to go, chomping at the bit and I explain to the broker that we can move as quickly as the seller wants. As it happens, they want a fast sale having been messed about and strung along earlier in the year before the boat was officially advertised. They want to try their hand at sailing and are keen to move on to their next adventure before the season kicks in. They come back with a mid way counter offer. Considering the condition and the work that has been done to the boat in their ownership, we’re happy to come up to this figure.

Contract negotiation

What follows are some contractual complications, I don’t like the ABY contract wording in respect of risks/damage to the boat pertaining to the buyer on sea trial, in my view the boat is insured by the seller at this stage and any risks shouldn’t be born by an uninsured potential buyer particularly when the sea trial isn’t an unaccompanied event, the seller or his representative will be present at all times and will be conducting most of the piloting. We propose some amendments which fortunately the seller pragmatically accepts because this could have frustrated the whole deal, no one likes to think of the ‘what ifs’ but the wording in the contract is just too open ended in the event of any damage. A survey is suitably arranged and the props are in motion! From viewing the boat on the 14th April to an offer made on the 18th April, counter offer and acceptance on the 23rd April, deposit paid the same day and survey arranged for May 4th which was postponed to 5th May due to bad weather.

Sea Trial & Survey

The 5th of May comes around, we have only seen the boat out of the water, it’s now back in, sadly my wife can’t make it as she has school runs to tend to. The comfort of the ABY contract is that the parties are all somewhat committed, barring any major faults with the vessel, or the buyer can pull out for whatever reason if not happy with anything on sea trial, if notified within a certain time window. I’m confident that the boat is good having already gone through it carefully. However I hadn’t heard the engines yet or seen how it would perform so there is fortunately scope to back out if we really aren’t happy with anything.

The weather is as anticipated but we’re all committed to make it happen. It was almost winded off the day before the sea trial but Studland bay affords certain protection it would seem and they all seemed to have plan of what route to take. There are 4 of us, the seller the buyer the broker and the surveyor. The surveyor was there early with the broker, I was asked to come a bit later to give the surveyor a chance to go through stuff without any distractions. We have been speaking to our chosen surveyor for a few months now since he was the one that had surveyed boat number 1 for the other buyers. He was going to go to the Netherlands to survey no.2 before it sold and he was arranged for boat no.3 before being cancelled, basically he had lived through the process with us and was always helpful and professional. I had every confidence in him. Sure enough, on arrival he talked me through some minor observations, but largely he was impressed with the condition overall. In fact, more than impressed.

We head out from Cobbs Quay towards the bridge to head out toward Studland Bay. The plan is to go out and do the sea trial, then head in to Dorset Lake Yard to have the boat hauled for the hull survey and then head back to Cobbs. Waiting for the bridge has the engines ticking over, my first impressions are that they seem much louder than the Yamahas in the Martinique, there is a rattling come from various places, I put my foot over the engine hatch flap and one rattle stops, the entry door is another one, the wet bar cupboards another. These are all easily remedied but the clattering would drive me mad. As the speed picks up the engines seem to quieten, that annoying frequency causing everything to rattle is gone, when the turbos start to spool the engines sound great. As we settle in to a cruise there is still an amount of engine boom which concerns me because I don’t know how the wife will take that, I’m assured by the surveyor that with the Canvas covers up as they are due to the bad weather, it is amplifying the sound of the engines and that it would be a lot quieter when the boat is ‘open’.

The weather conditions couldn’t have been much worse. The sea is choppy and hailstones rain down noisily pelting the canvas and even the one screen at the helm that was open needs buttoning back up due to hailstones coming in!

The boat sits beautifully in the water, it’s very planted, smooth and feels reassuringly stable. We hit 30 odd knots at 2750-2800rpm when we go through the revs and it’s fantastic to see that the temps don’t exceed 80 odd degrees. We are carrying a full tank of diesel and water and the 4 of us on a choppy sea. The Martinique had the temp needles heading to just under 100 and the same speeds. The under stressed nature of the Caterpillars with their huge 7,200cc capacity and massive turbo’s all playing their part to provide effortless torque and stable temperature consistency. The Portofino is on the plane at around 12 knots, those engines thrusting the bow and the stern to rise up over the ocean. A nice turn shows the boat is still suitably agile maintaining it’s stability. It’s a very comfortable platform. What looks huge in the marina feels very comfortable out on choppy waters.

We arrive to Dorset Lake Shipyard to have the boat lifted.

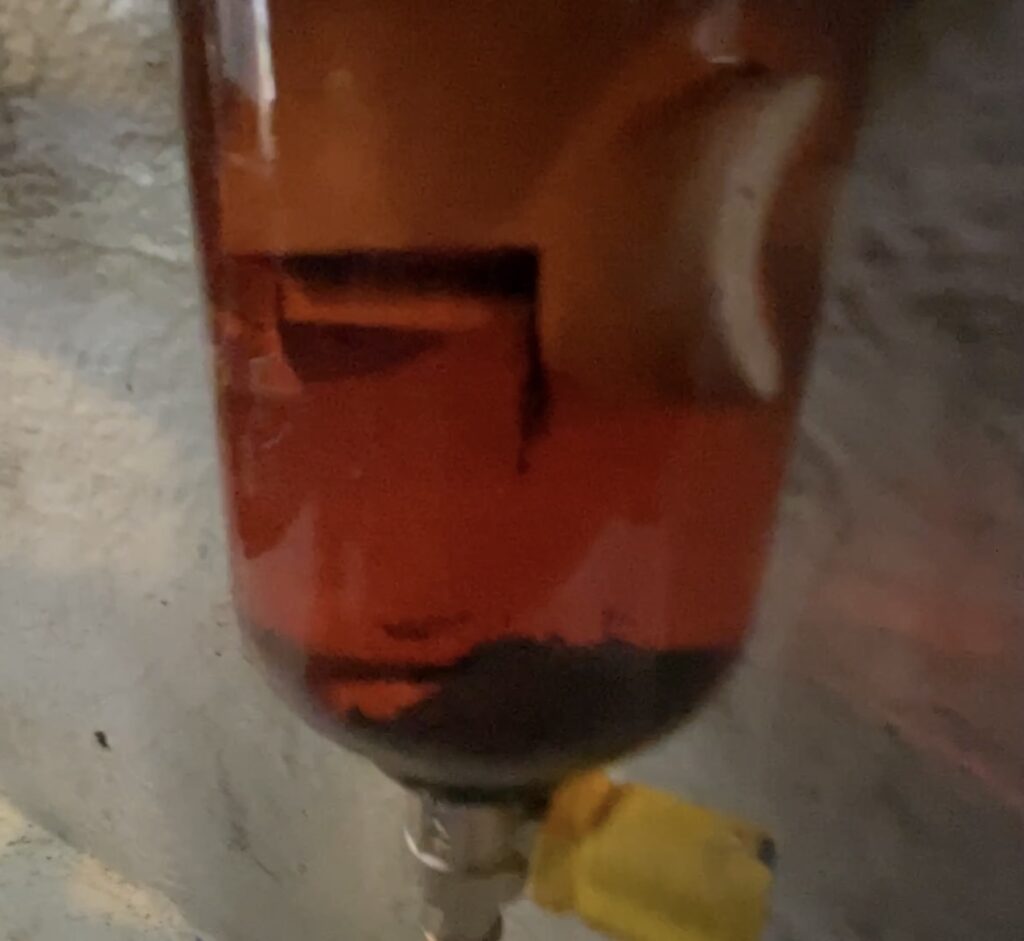

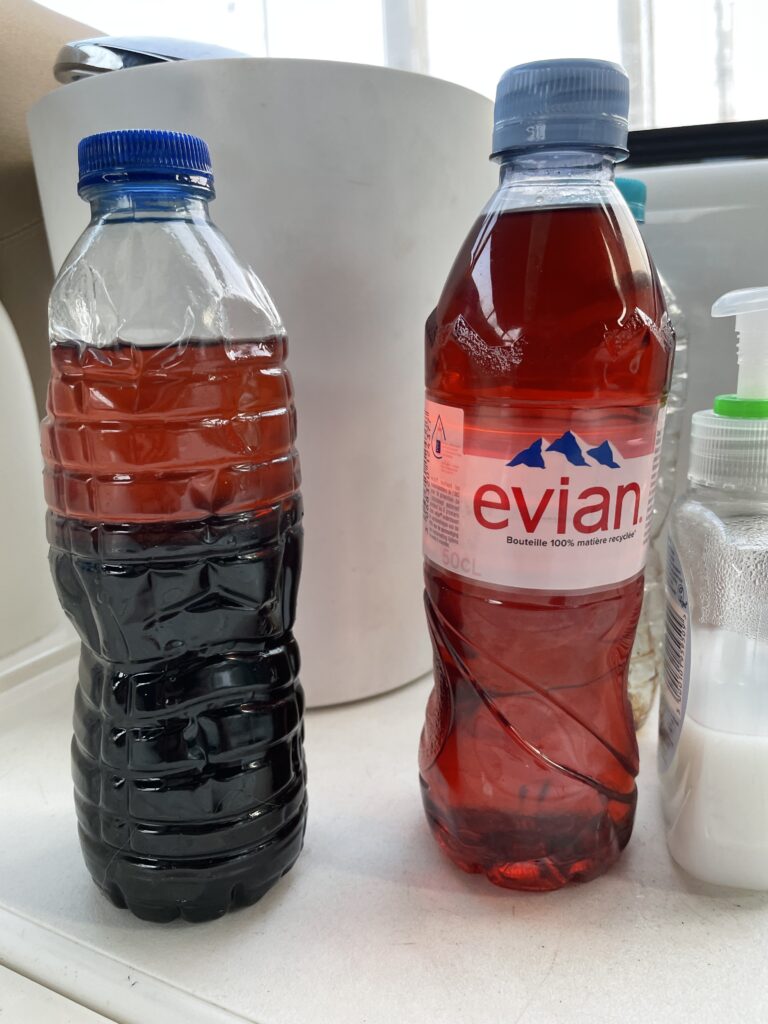

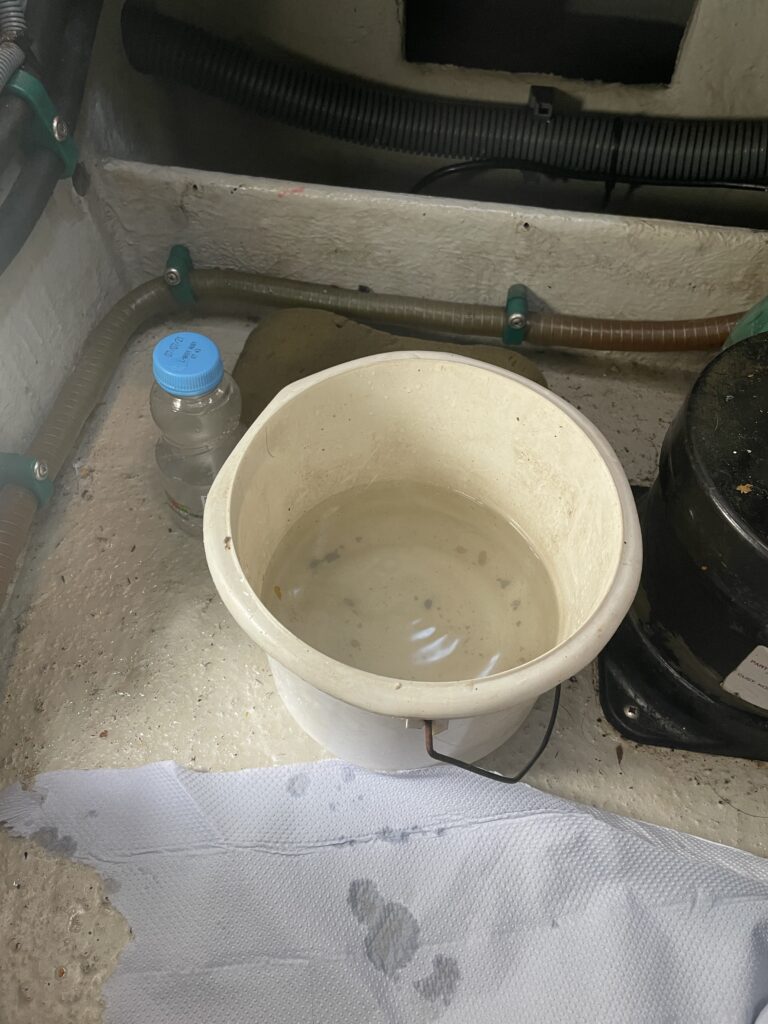

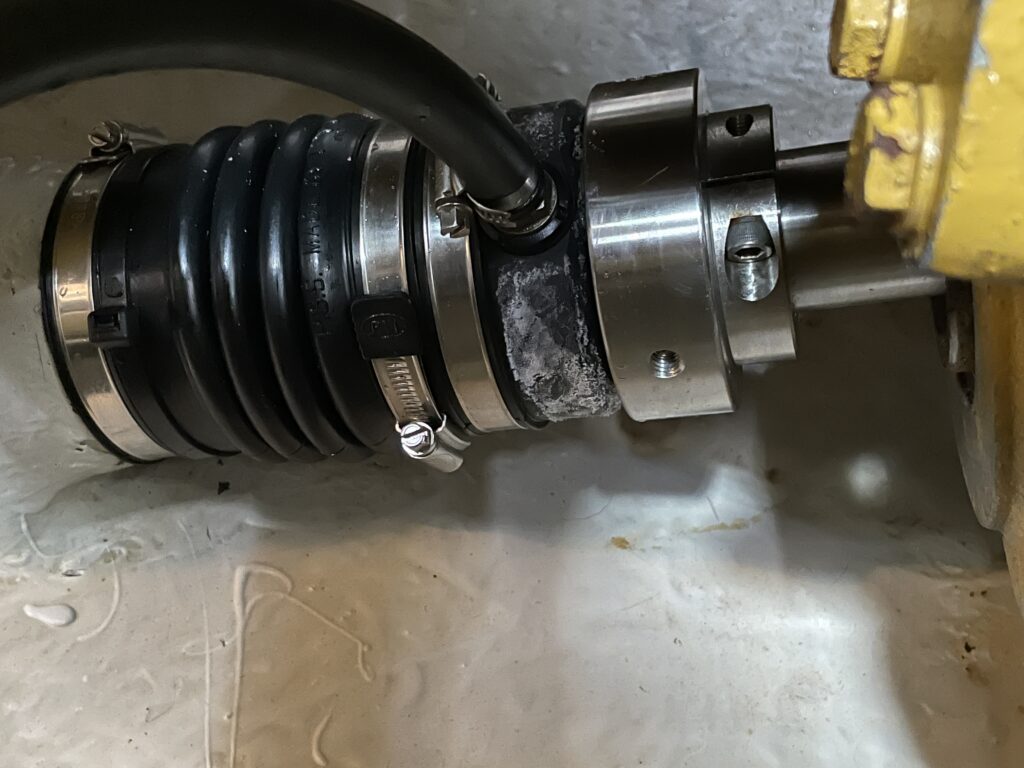

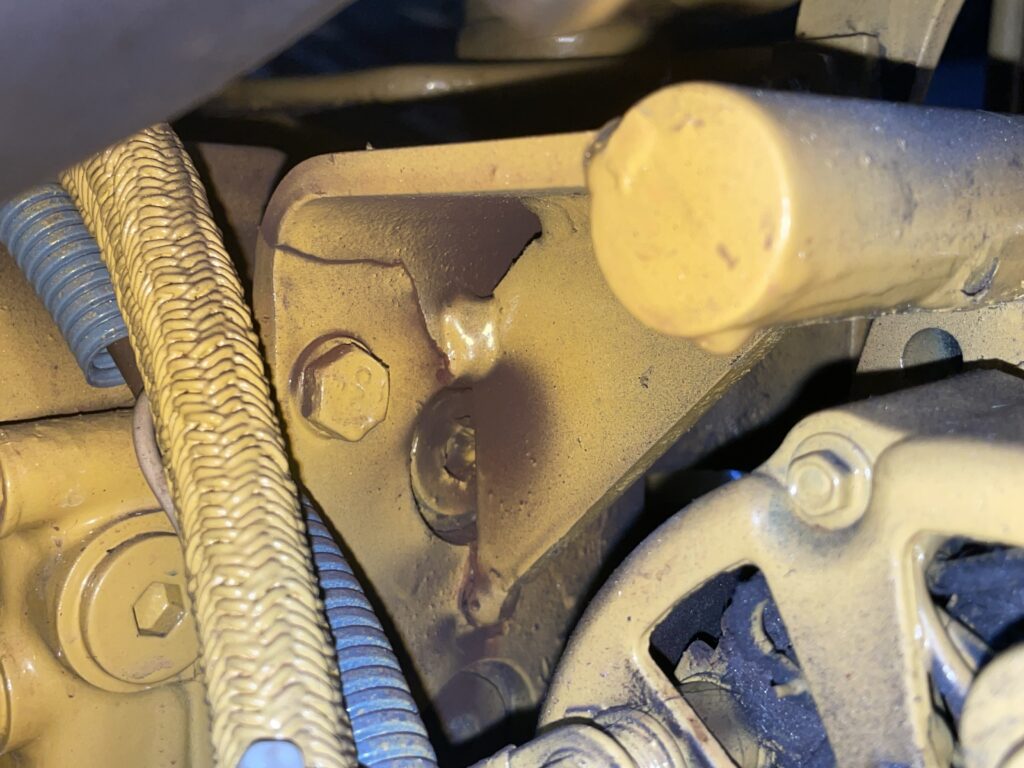

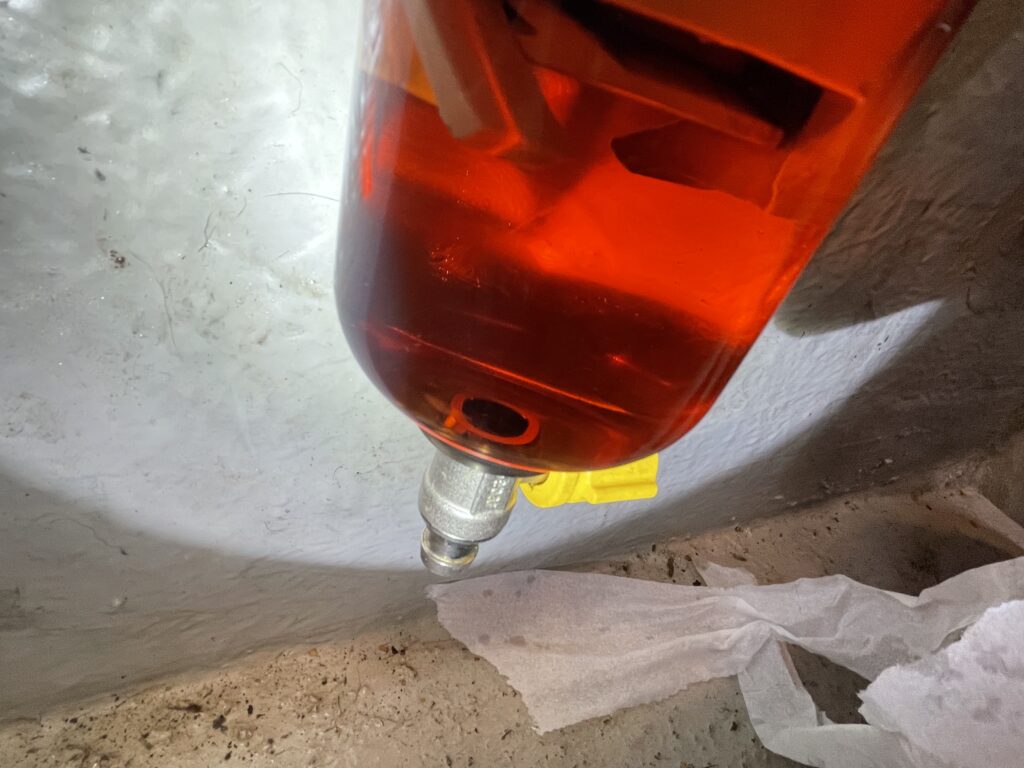

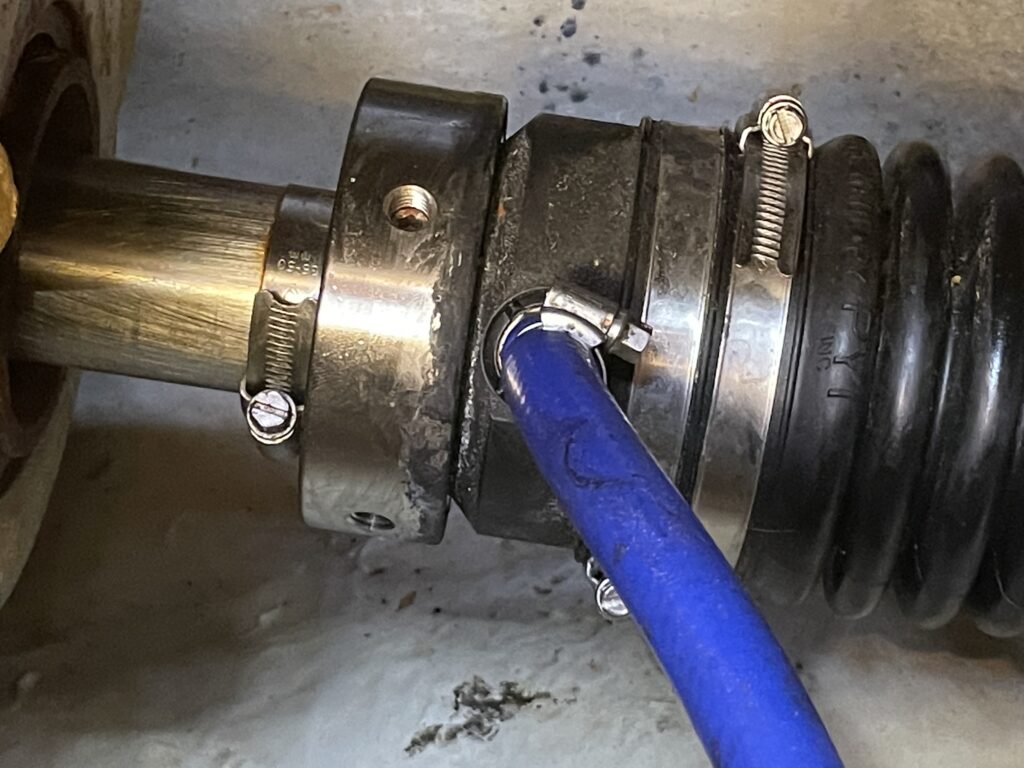

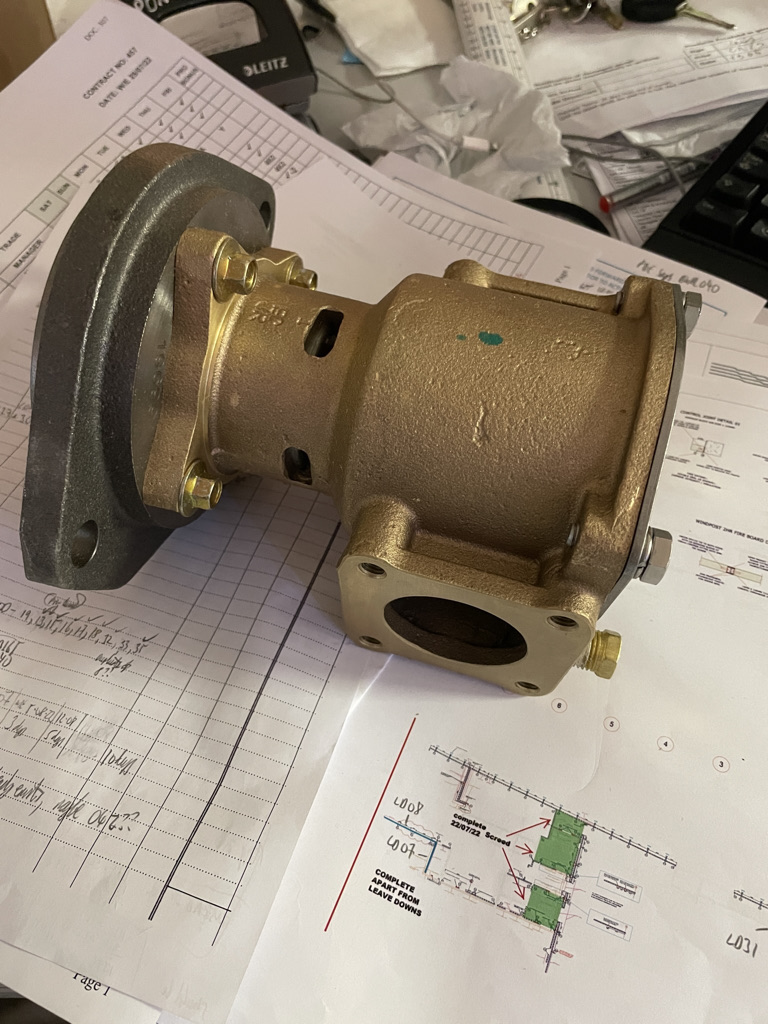

The surveyor does his thing with his moisture tester. The boat is giving off nice low readings “considered to be at the bottom of the range and of no concern”. The only real finding of any consequence is a tiny bit of lateral movement from the starboard cutlass bearing but nothing that required immediate attention, some exhaust lagging to be remade which was done prior to handover and the toilet discharge connection required remaking due to a light degree of seepage where the hose is seated, that was pretty much it. During the post survey phone conversation with the surveyor on the way home from the survey, he tells me, there is absolutely no reason why you should not buy that boat, it’s a good one. When the survey report lands the conclusion states “The vessel was found to be in excellent condition, no attention is required and the vessel is considered to be a very good example of her marque.”

Completion & Handover

Following the successful survey, we formally accept the vessel and move on to paying the remainder balance. We are fully paid up for the vessel by the 12th May and we finally complete formalities and handover on the 15th May. From first contact with the owner on the 12th April and subsequent viewing to fully paid in less than 4 weeks and full completion in a touch over 4 weeks. Not bad going at all!

Handover day arrives, once again my wife can’t make it so her Father comes along instead. After signing all the necessary paperwork and exchanging bottles of alcohol, the previous owner kindly goes through all the ships systems in thorough detail. I have brought along a pen and notepad to take notes and I’m armed with a whole load of questions. As the most recent owner, no one knows more about the boats peculiarities than him, having been a hands on owner himself there are many tips I can pick up from him to familiarise myself quicker. There’s a lot to take in but thankfully it all makes perfect sense. Generously and very conveniently for us, the previous owners have given us use of the mooring until the end of the month so essentially we need to vacate by end of May which gives us a 2 week window to get the boat home to her new mooring…