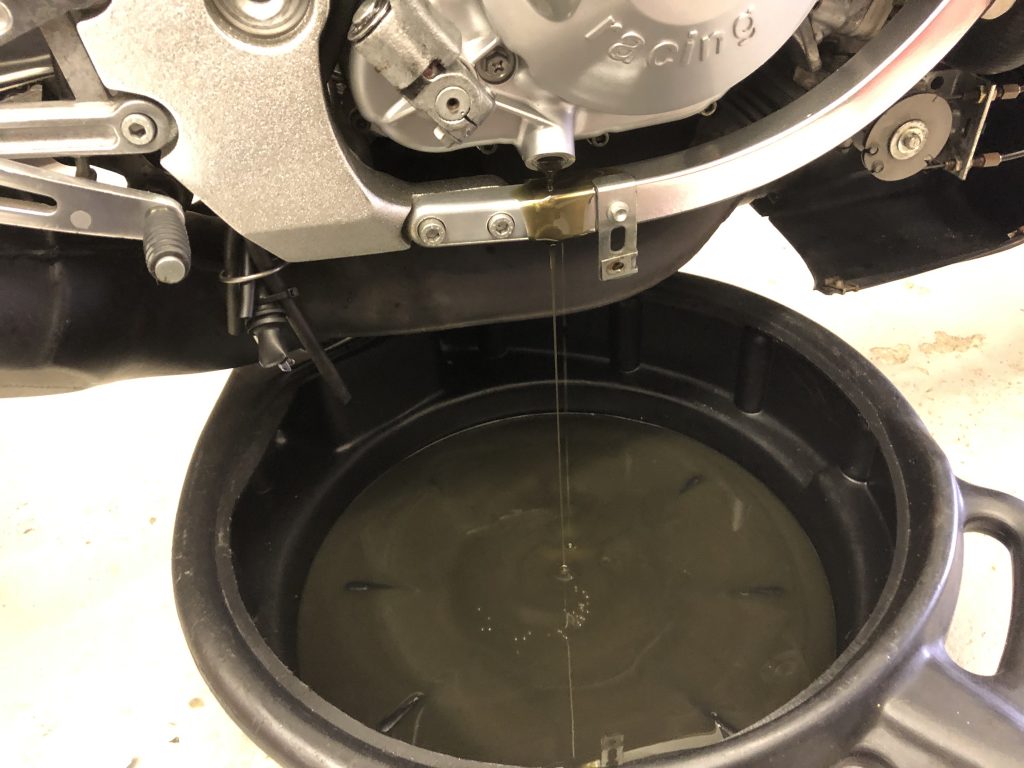

The gearbox oil was last changed about 400 miles ago, and about 20 years!! So despite looking reasonably clean I drain it out for replacement. I drain out over 800ml.

The oil plug is also relatively clean.

Cleaned off and ready to reinsert!

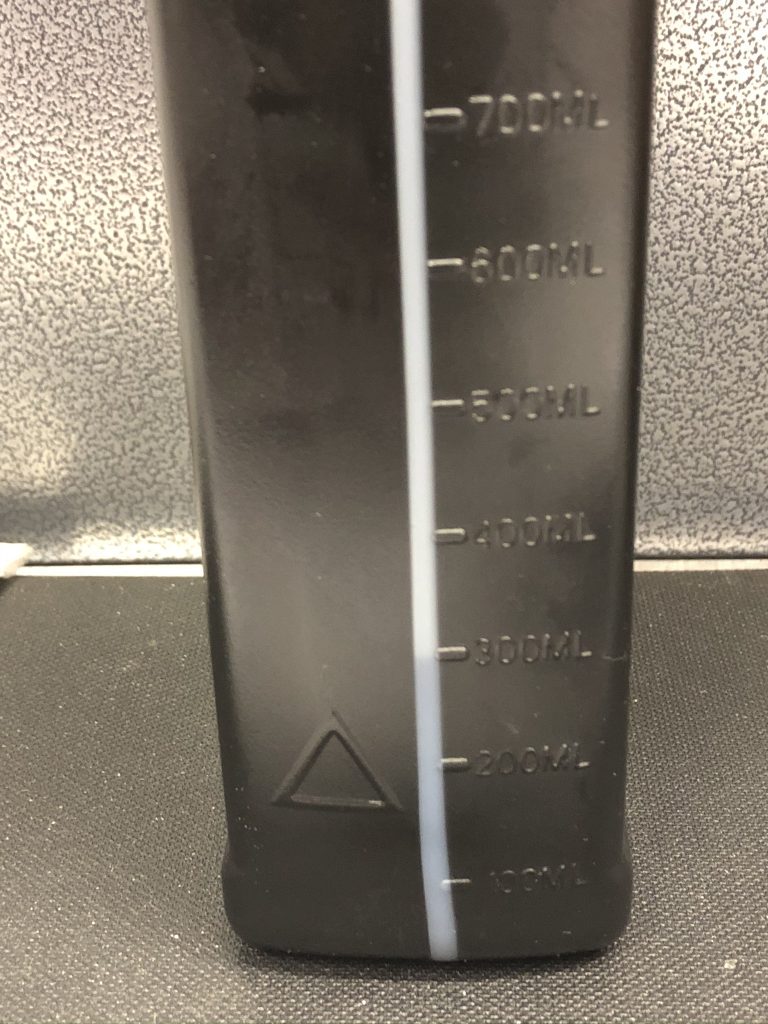

On the advice of the tuning works, I go for Silkolene light gear oil, and fill it to the correct 700ml measure.

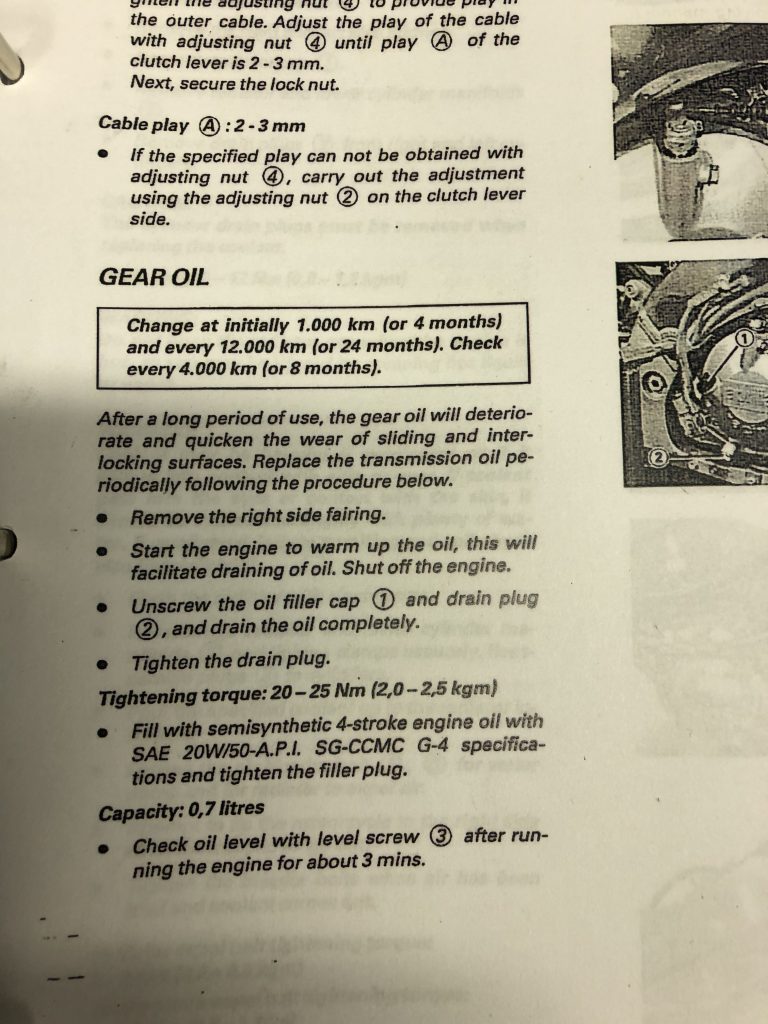

However after consulting the manual, it looks like Medium gear oil would be the correct choice! As a result I shall probably drain this out and replace with medium soon!!

From reading the Silkolene data sheets, Gear oil ‘medium’ is the equivalent weight to engine oil SAE 20W/50 as called out in the manual. Gear oil ‘light’ is a 10W/40.

The original crush washer was clearly reused previously and crushed to nothing! I fit a new washer to the correct torque setting.

Edit:

Gear oil light I feel is too thin, so it has been replaced with medium, a mere 40 miles later!!