In the incredulous words of ‘Talking Heads’ ironically titled, “Once in a Lifetime” song, “Good God…….what have I done?” As I sit here trembling from nervous energy, I’m excited, ecstatic, nervous and bricking it, all at the same time in countering waves. I’ve just placed a deposit on a once in a lifetime bike. A bike that I was smitten with from the first time I clapped eyes on a picture of one…may soon be turning into a reality.

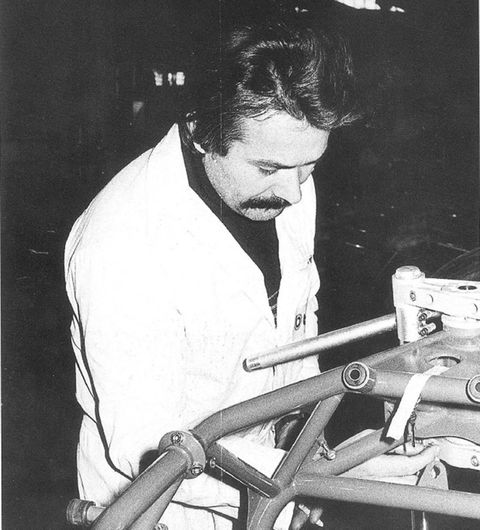

It’s a totally impractical proposition and will be the most valuable bike I own, hard to justify on any logical level as a ‘motorbike’, but this truly is so much more. It’s not ‘just’ a ‘motorbike’ although it is that, and a fine one at that. It is not just ‘art, although it quite easily qualifies for this, it’s not just an ‘engineering masterpiece’ for it is also this too. It is the origin story of the greatest and arguably most influential motorcycle designer/engineer that has ever existed. A man that defined at least four decades of motorcycle creations. The genius behind Bimota, Cagiva, Ducati and MV Agusta’s finest models.

I am a huge fan of Massimo Tamburini. It runs much deeper than this though, there’s an aura of energy that radiates from his machines, one that ignites the kindred soul within, an affinity for what he set out to achieve and an admiration for his engineering execution to meet those big visions that he dreamed for himself. I share this empathic bond with the great man when in the presence of his works. It’s about having an appreciation for his engineering prowess, always pushing the envelope and breaking with convention for nothing more pure or sincere than a love for the pursuit of excellence and beauty on a granular level.

His intense attention to detail pushes everything way beyond what was strictly necessary or commercially viable, driven by a true passion to create perfection in the process, channelled through an unwavering dedication and a focused determination. This is, motorcycle art! I admire the execution of the solutions he devised and find myself in awe of the detail evident in his creations. There are so many little touches, nuances, traits that strongly pervade all of his works, works that are defined by boldness, risk, courage, sacrifice, passion, intelligence, imagination, love, perseverance, energy, precision and excellence. It is engineered into the DNA of all of his motorcycles, only truly visible to those who truly appreciate.

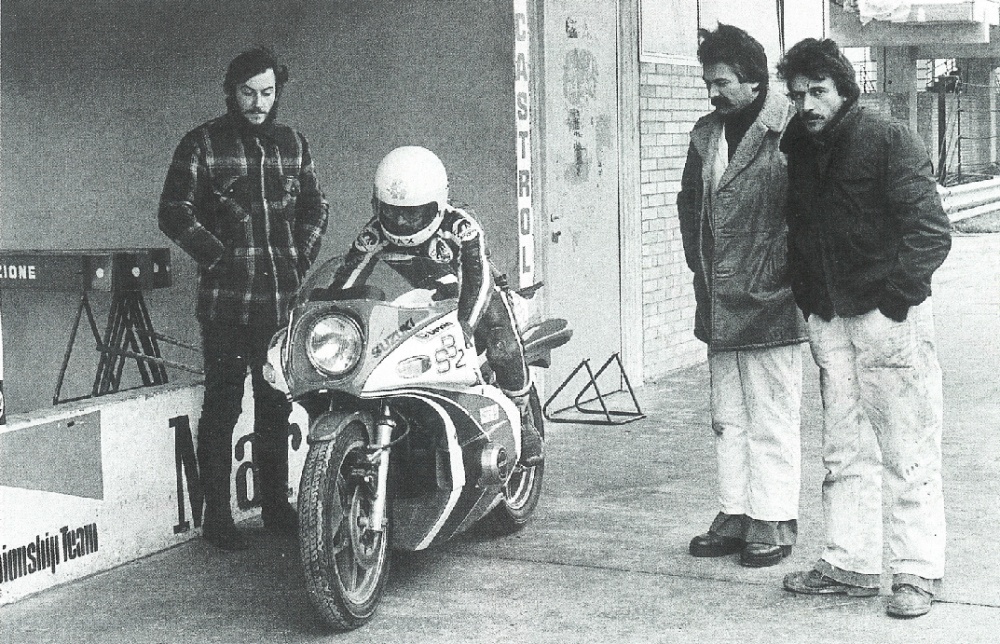

The Bimota SB2, is the first complete road bike designed by Massimo Tamburini, hot off the heels of his direct contribution to the Bimota framed Championship winning Yamaha powered motorcycle of Venezuelan Johnny Cecotto who won on the opening race of the 1975 350cc Championship and finished the year defeating the legendary and undisputed Seven time defending champion, Giacomo Agostini, providing Johnny with his one and only 350cc World Championship crown.

Having established his own company, ‘Bimota’ in 1972 with 2 other friends (Bianchi/Morri/Tamburini) initially as heating system engineers, it was soon renamed Bimota Meccanica in 1973 when they began producing race chassis frames for racers. Buzzing with the victorious energy and the confidence from his race success, Tamburini turned his attention to Bimota’s first road bike, the groundbreaking SB2. A ground up motorcycle which was exhibited to the world for the first time at the 1976 Bologna Motorshow.

This model carried the pressures, the success, the hopes and dreams for the future of Bimota. This was Tamburini’s Genesis, his first true creation. As such, it is possibly one of the most interesting and exciting motorcycles produced in my timeline. Conceived and born at the same time as me, this fabulous creation is my motorcycle doppelgänger.

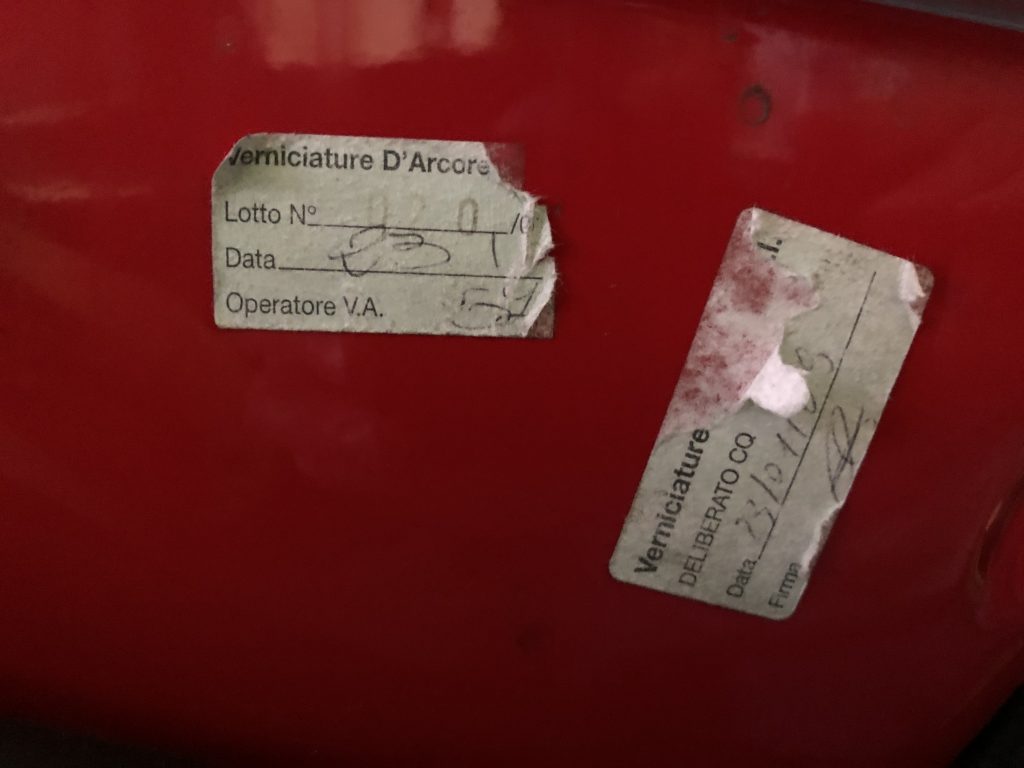

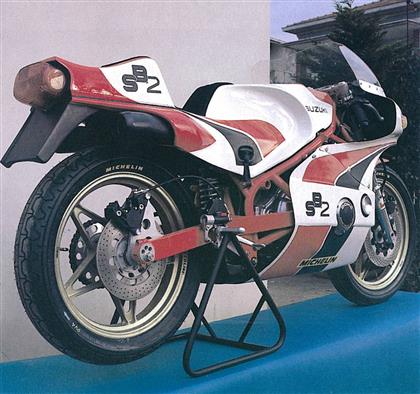

1976, and here was this radically designed motorcycle that looked to have come from another planet compared to contemporary forms of the time; all swoops, curves and presence, patiently and lovingly sculpted, applying his all, the bike encompassed so much more than the beauty it’s bodywork exuded, for it contained within its wrapper many world firsts and concepts which remained a Tamburini hallmark throughout his career.

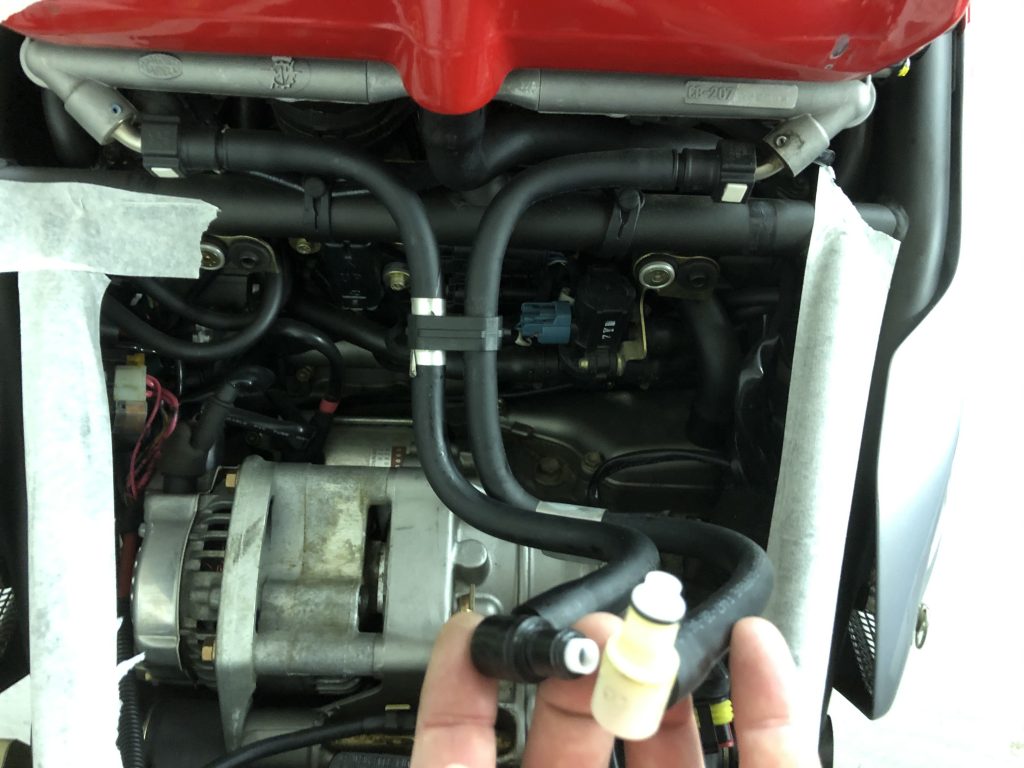

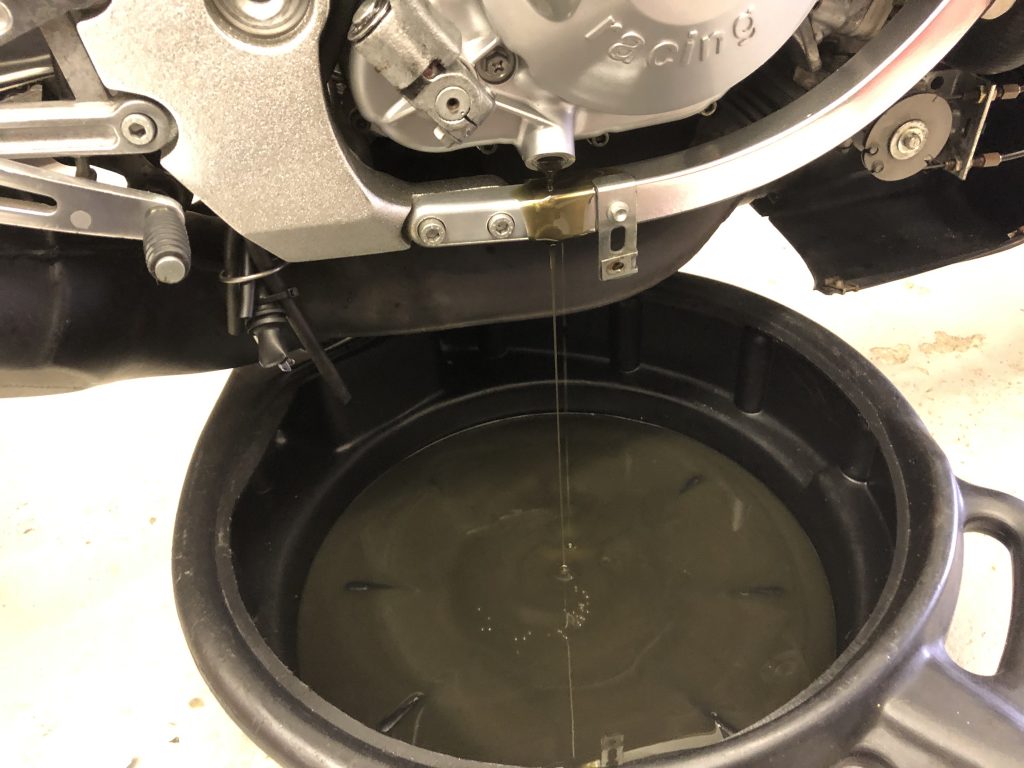

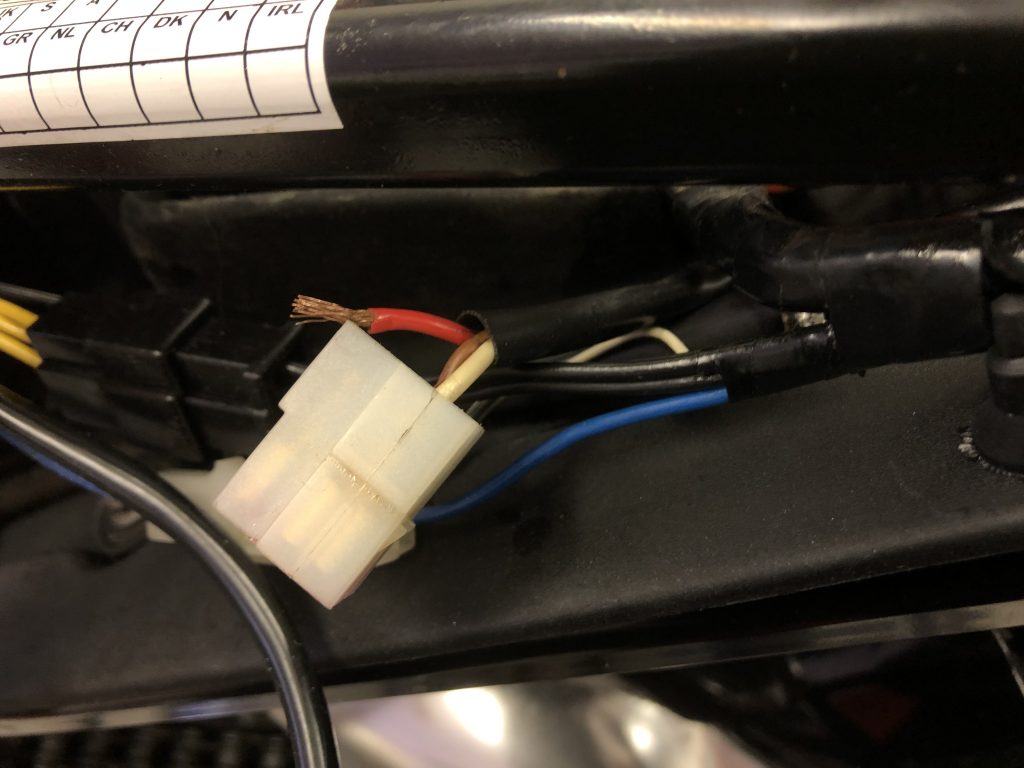

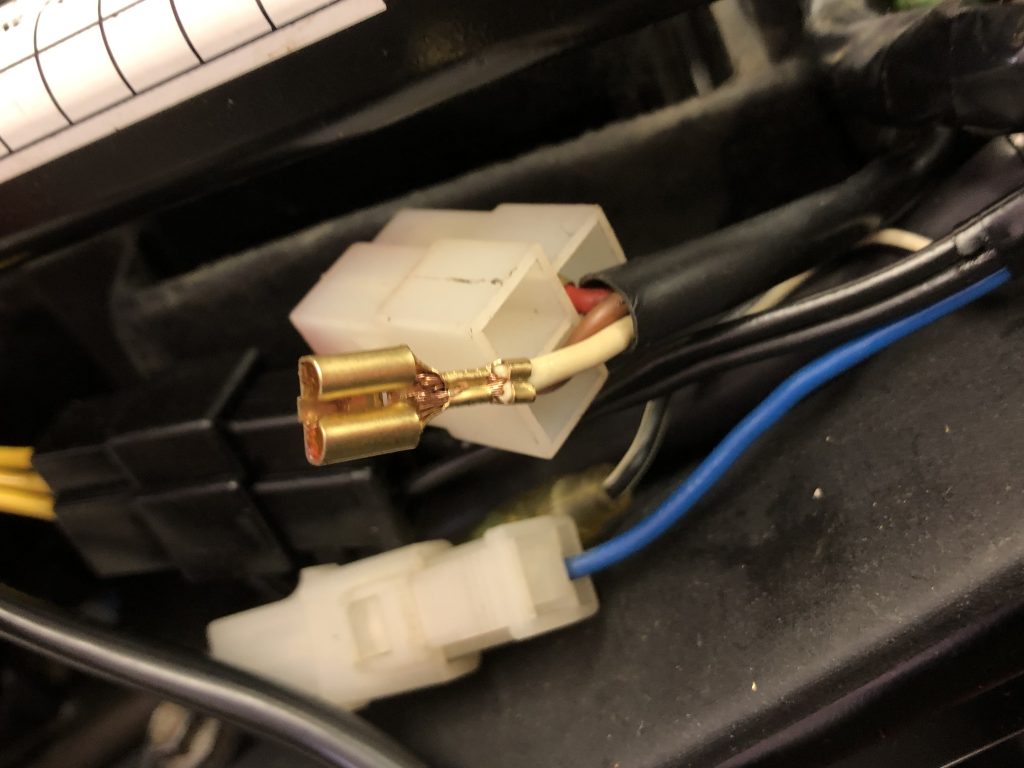

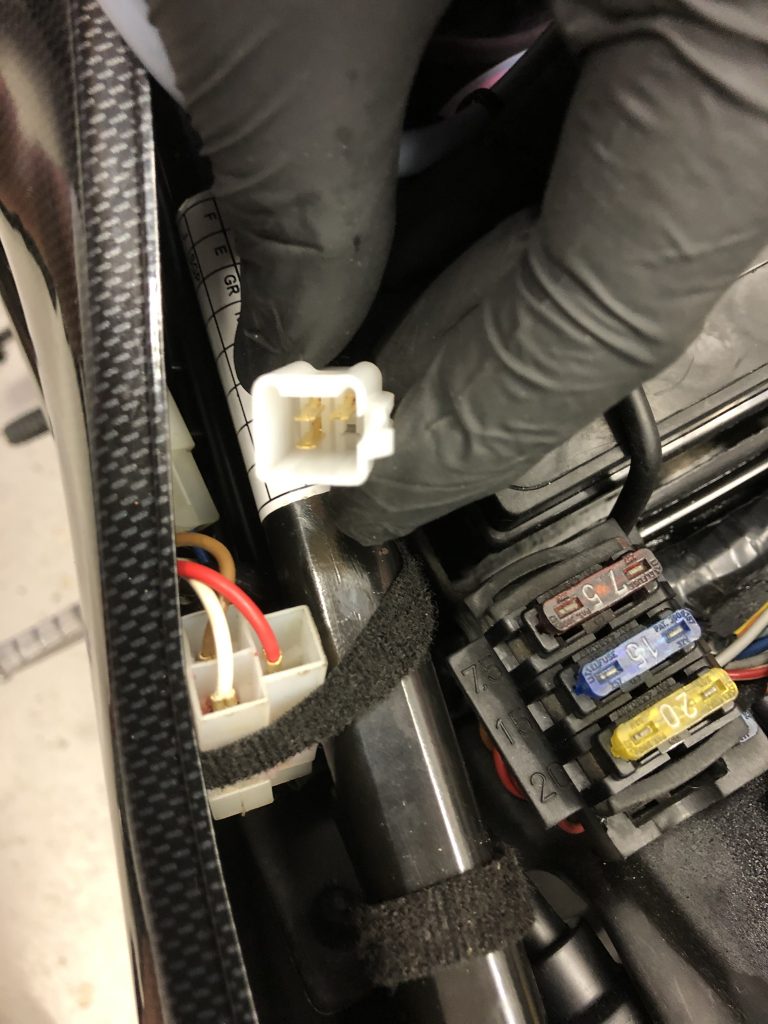

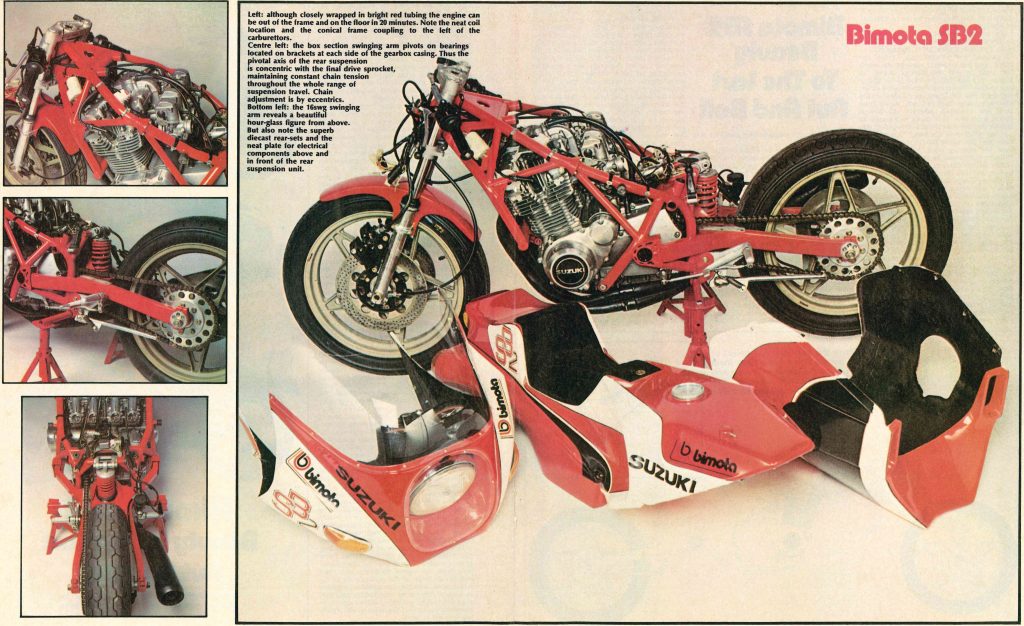

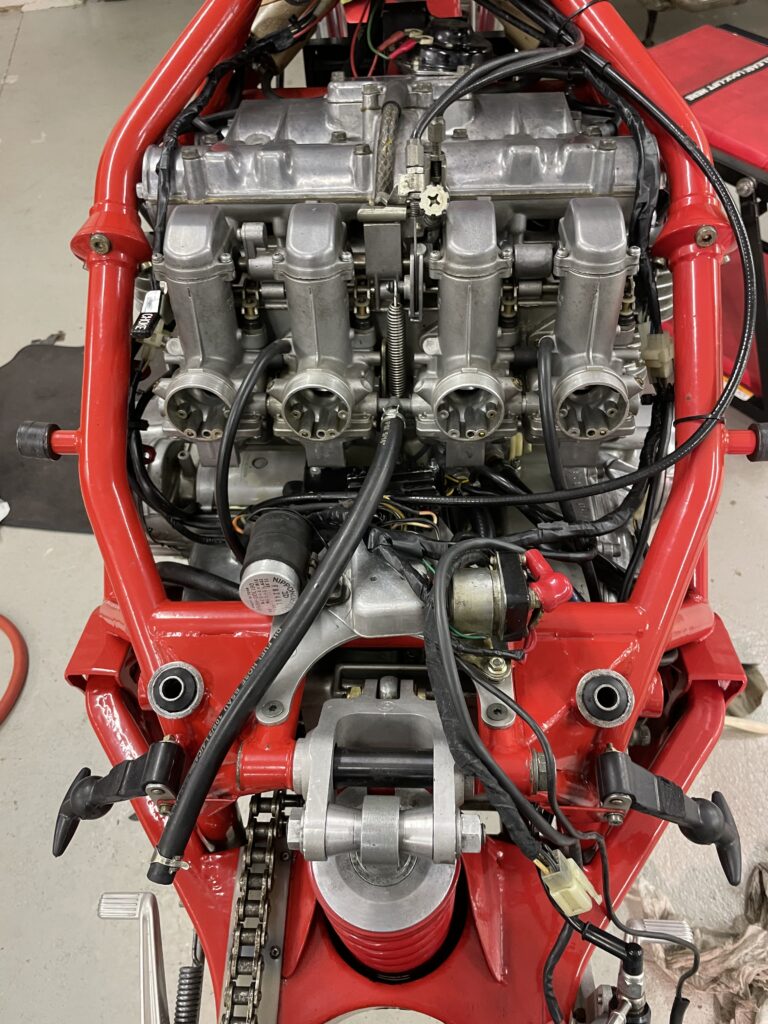

As anyone who has worked on one of Tamburini’s great designs will appreciate, the intelligence of his creations manifest themselves the very first time you begin to disassemble the components to carry out maintenance. The bodywork always comes apart incredibly easily. As an owner, it is highly rewarding to strip the motorcycle down to it’s frame and engine in moments.

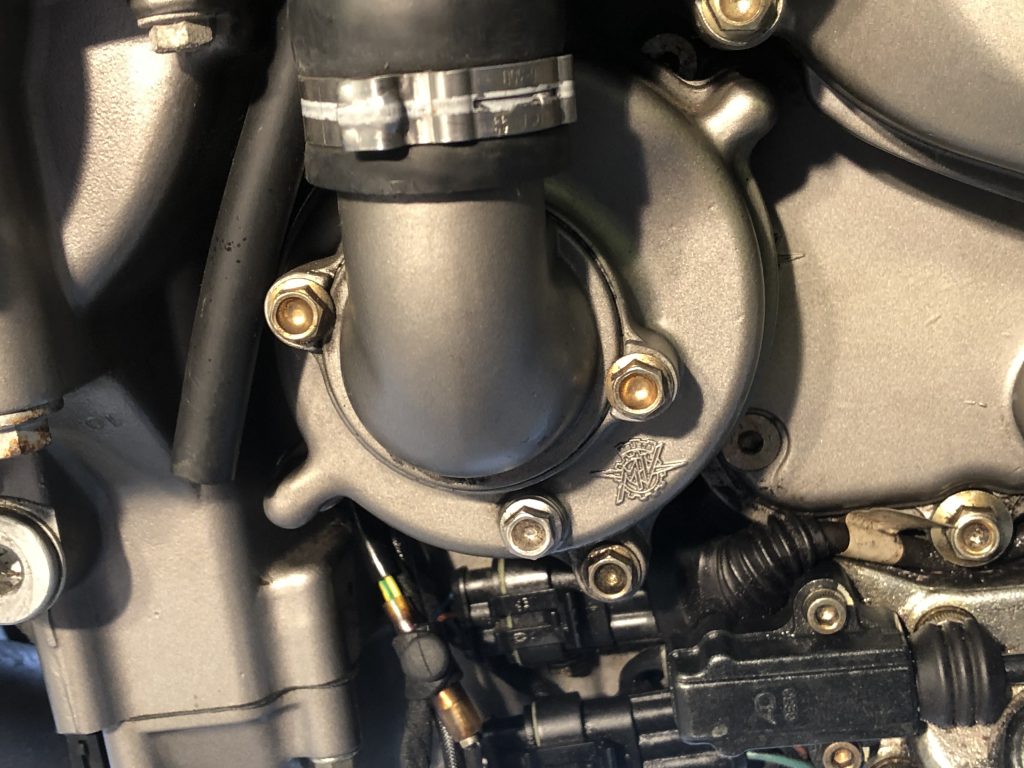

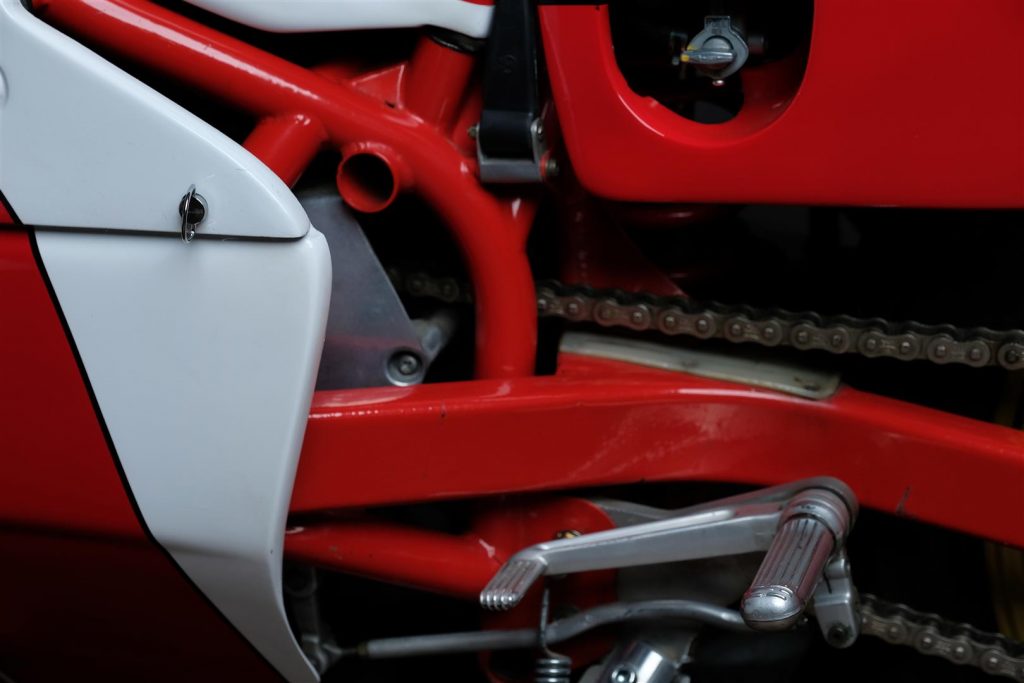

Going even further, it’s not just ease of access to serviceable items; consider the frame for instance, which uses the engine itself as a stressed member, it is designed so that it can be detached from the frame in mere minutes.

Beautifully engineered conical fittings provide strength and precise mating of the components while providing a substantial visual statement of intention, not just providing supreme rigidity, but boldly making that point with a heavily engineered joint for reassurance.

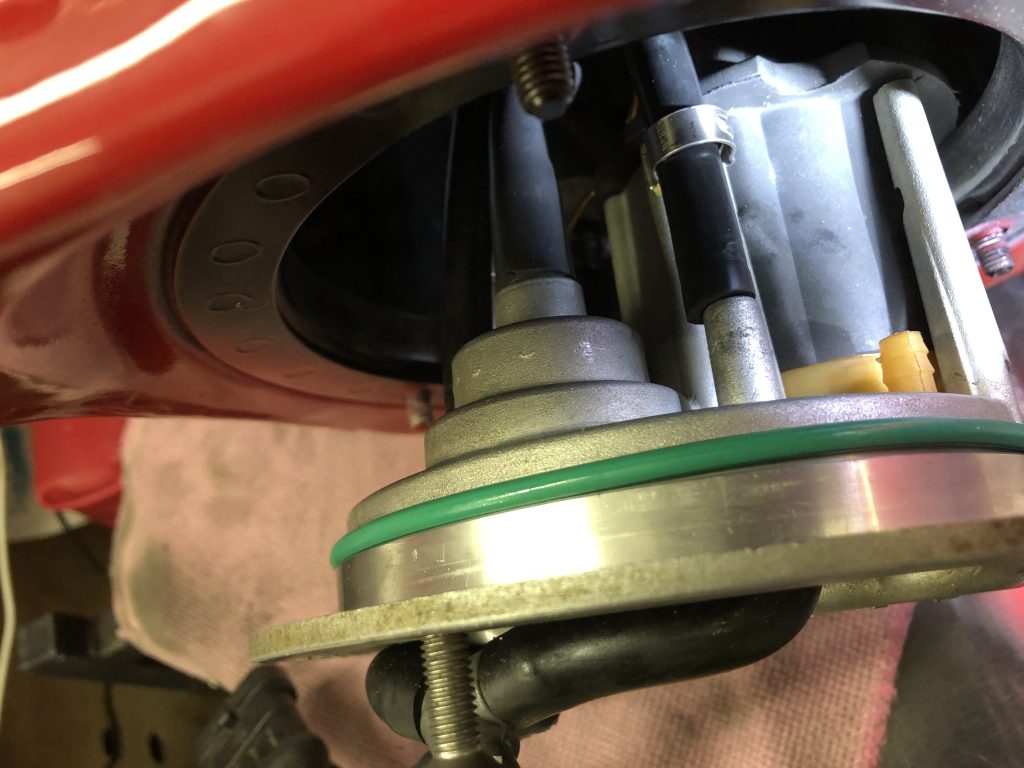

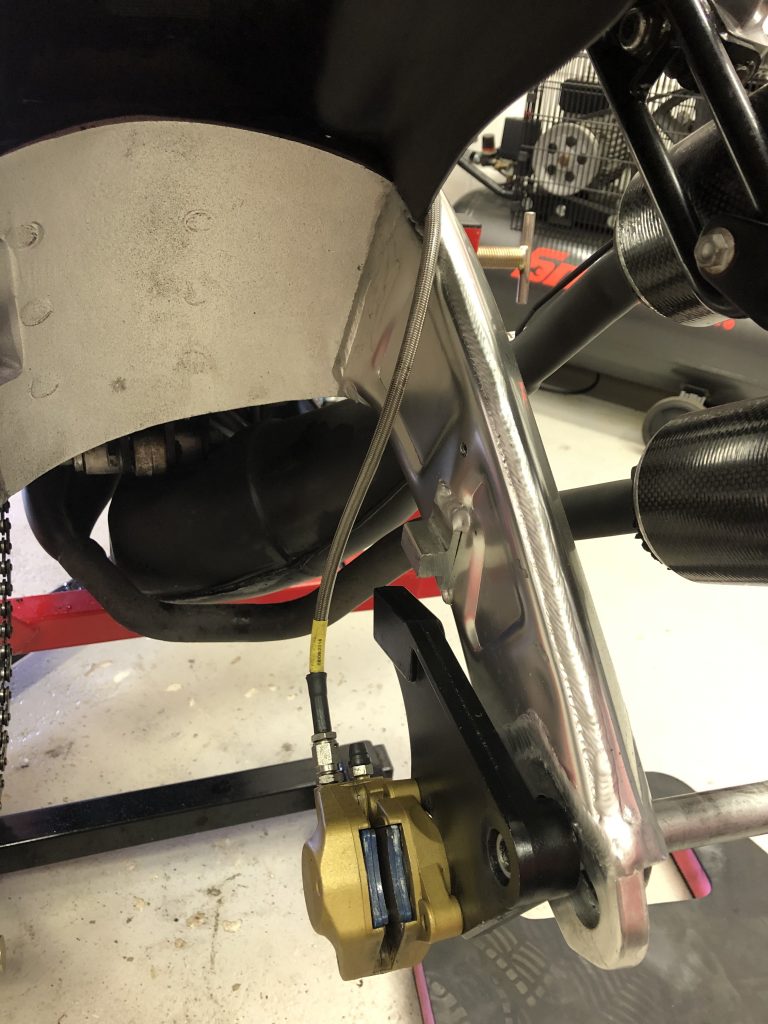

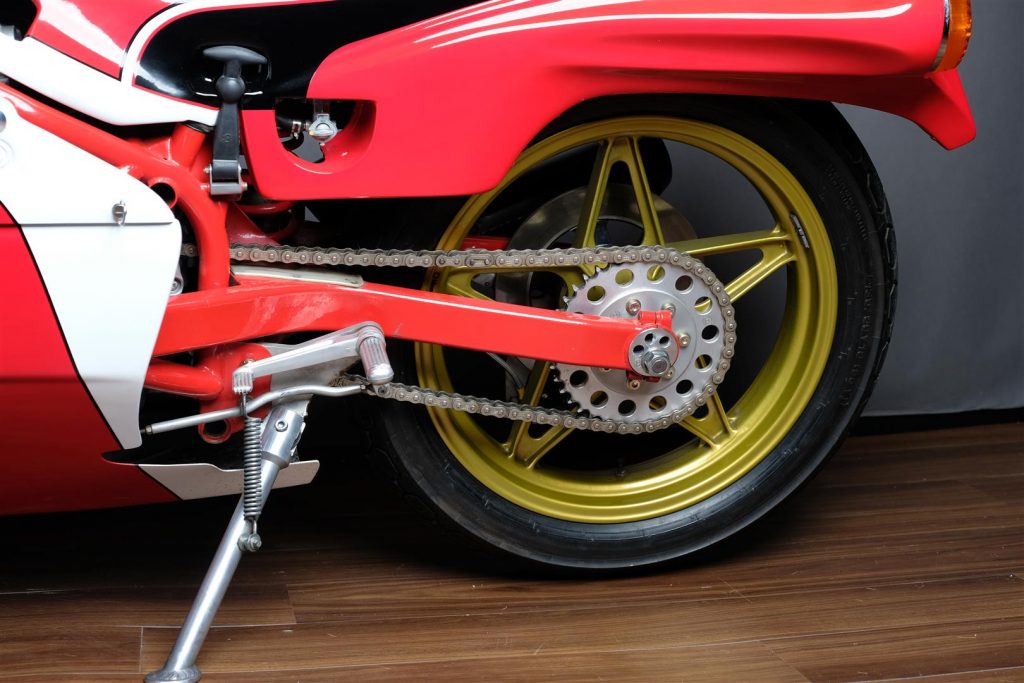

The rear end, uses an eccentric hub to adjust chain tension. This features in so many of Tamburini’s designs, the original Ducati Paso had the same setup, along with the later 916 and F4 which both additionally featured a single sided swingarm with the eccentric hub.

The eccentric hub meant that as the chain is adjusted, the rear ride height will change. Of course Massimo Tamburini had allowed for this with a compensation rod connecting to a rocker in the rear linkage to adjust the ride height precisely back to where it needs to be.

The rear swingarm pivot point, was aligned with the gearbox output sprocket, this allowed the rear end to maintain a constant chain tension throughout the arc of the swingarm’s movement and more importantly, all but eliminated rear squat under power. The use of the rear monoshock is also one of the first road bikes to deploy this setup.

At the front end, an eccentric hub in the triple tree allowed the offset to be changed to tune the steering response. This idea carried through to the F4 also. The forks were set in at an offset angle to the yokes (28 degrees from vertical) as opposed to the triple tree (24 degrees from vertical) to reduce rake/trail changes under braking for a more consistent geometry.

35mm Ceriani telescopic front forks and a Corte é Cosso rear shock absorber handled the suspension movement.

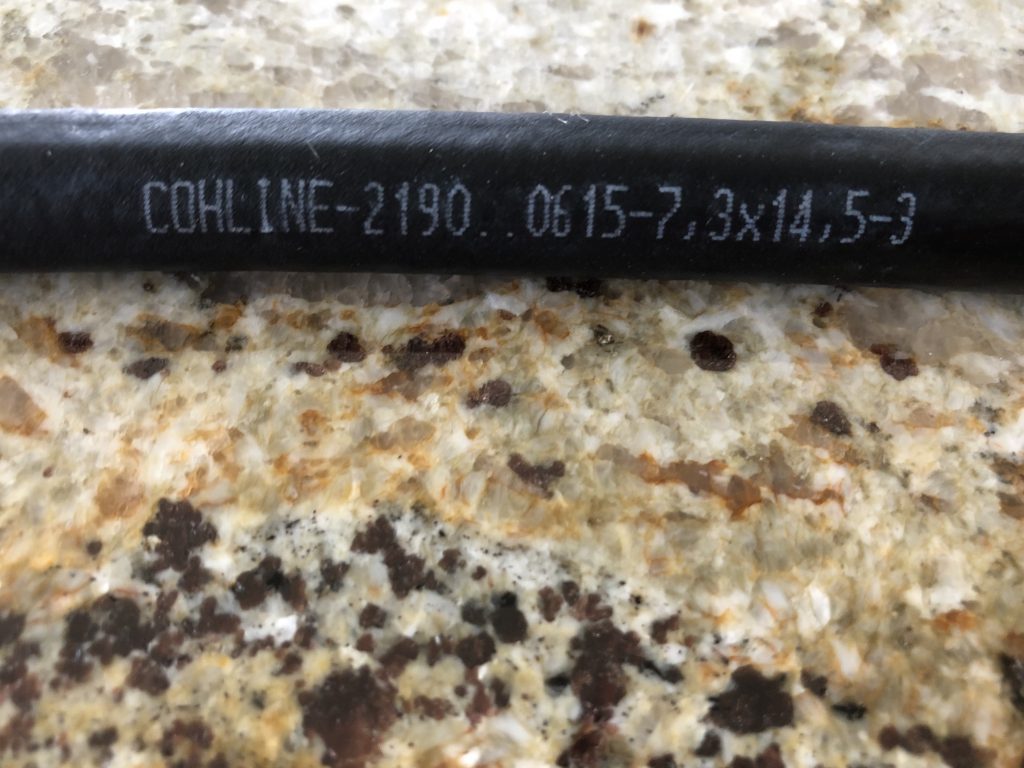

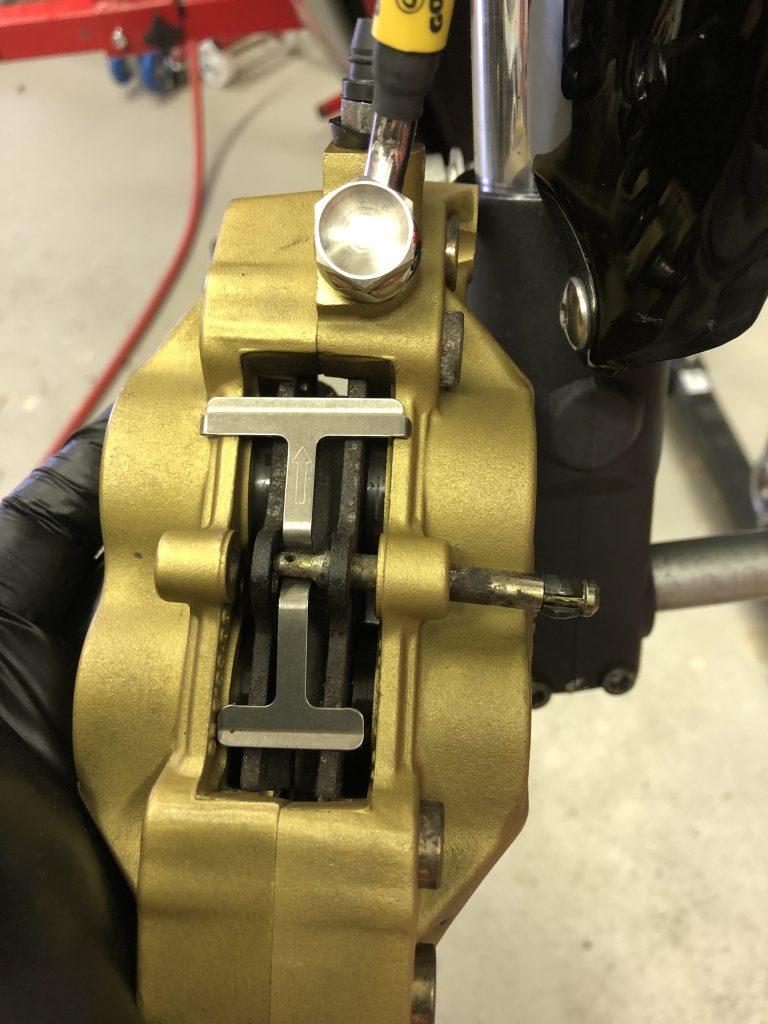

For deceleration, Brembo provided the braking power with twin 280mm rotors up front and a single caliper 260mm disc set up at the rear. These were married with Magnesium Speedline rims, fitted with the modern day equivalent of 100/90/18 to the front and a 130/80/18 rear tyre.

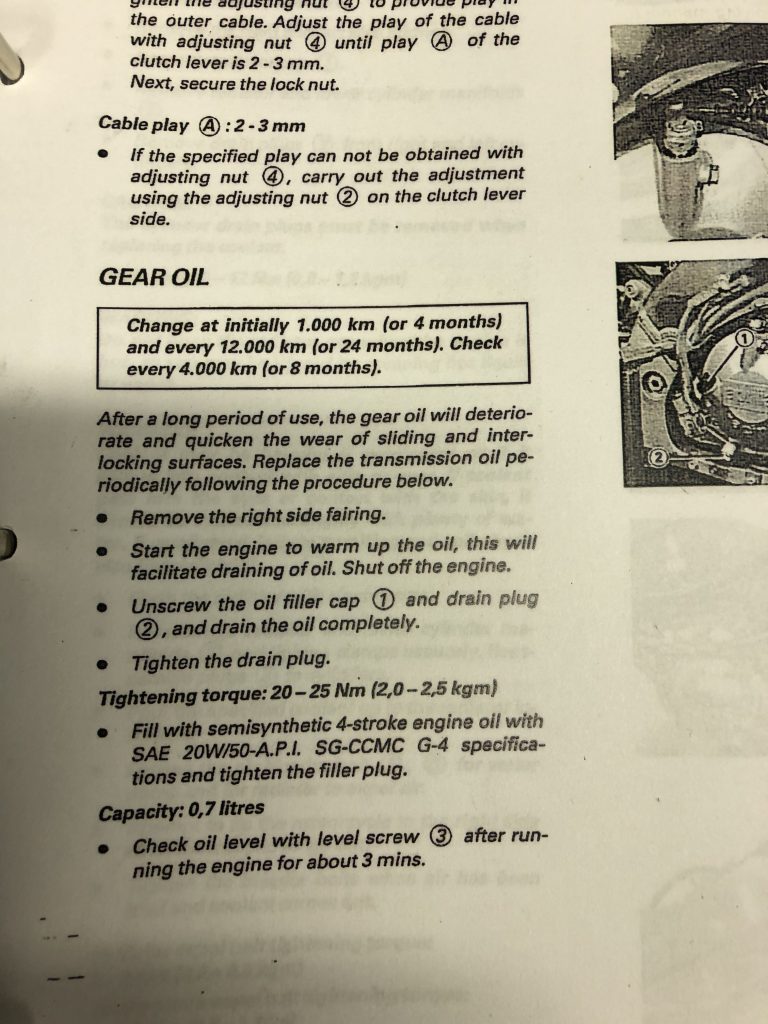

Suzuki provides the beating heart within the chassis. An 8v GS750 750cc inline 4 cylinder engine allied to Suzuki electronics and a 4 into 1 free flowing exhaust system are fitted as standard to the factory bikes.

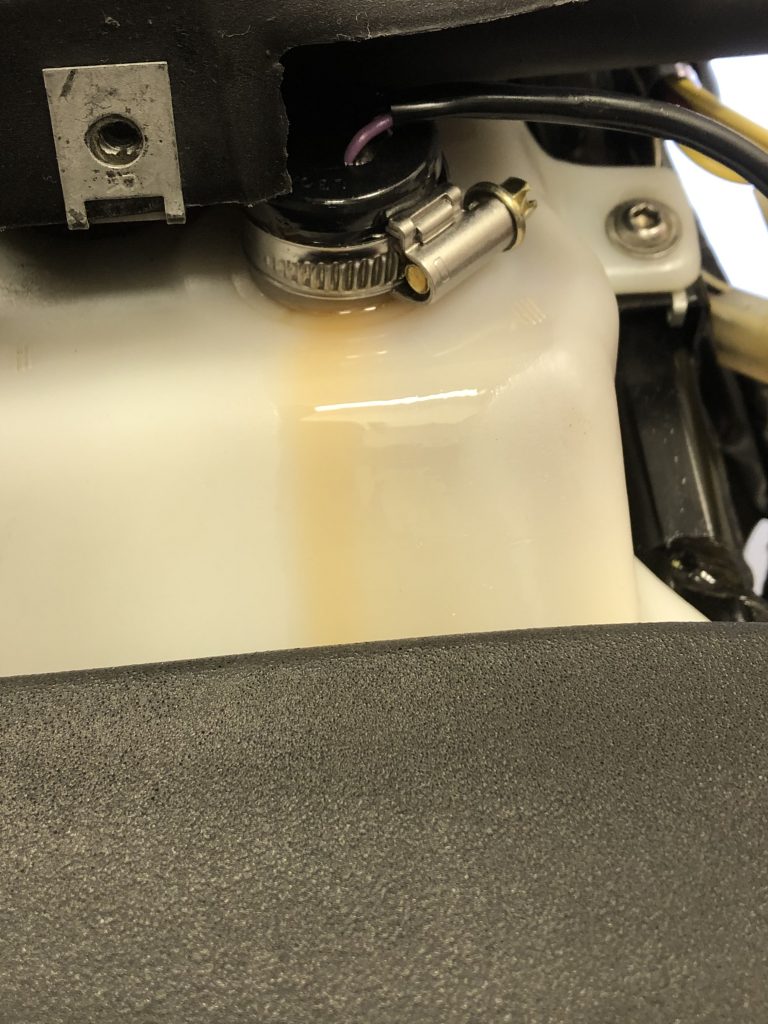

As a factory upgrade option, one was able to specify a Yoshimura 850cc engine as fitted to this particular bike. Yoshimura were a renowned Japanese engine tuner, synonymous with Suzuki courtesy of the solid reputation they had earned from all their racing success with tuned Suzuki engines.

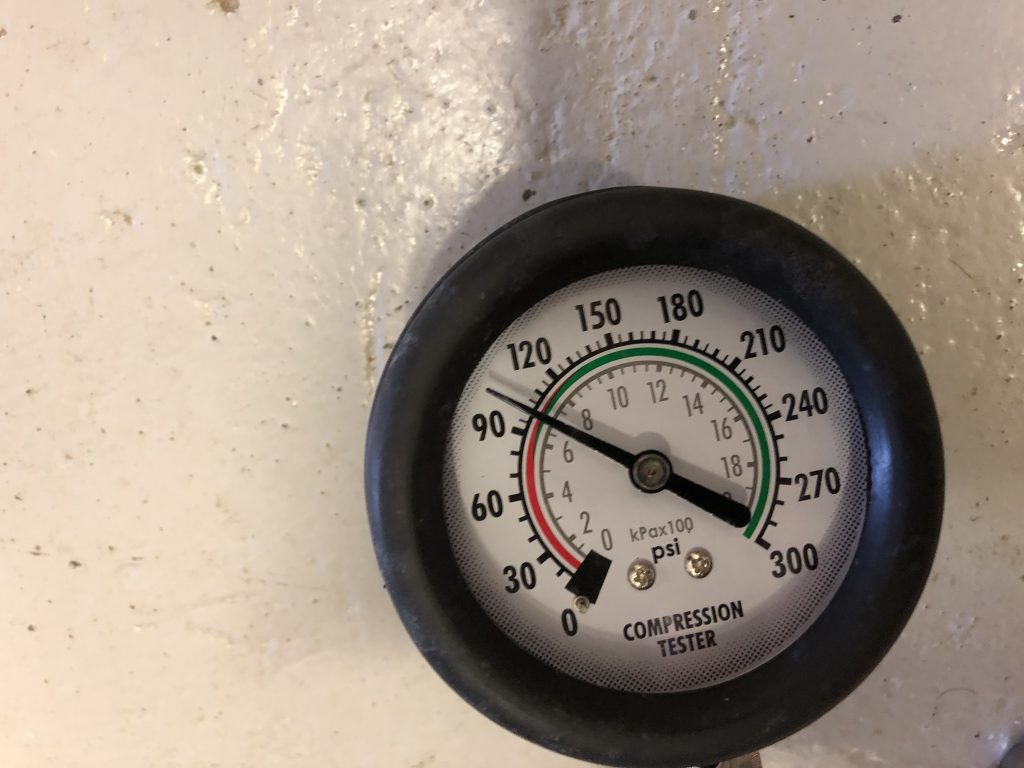

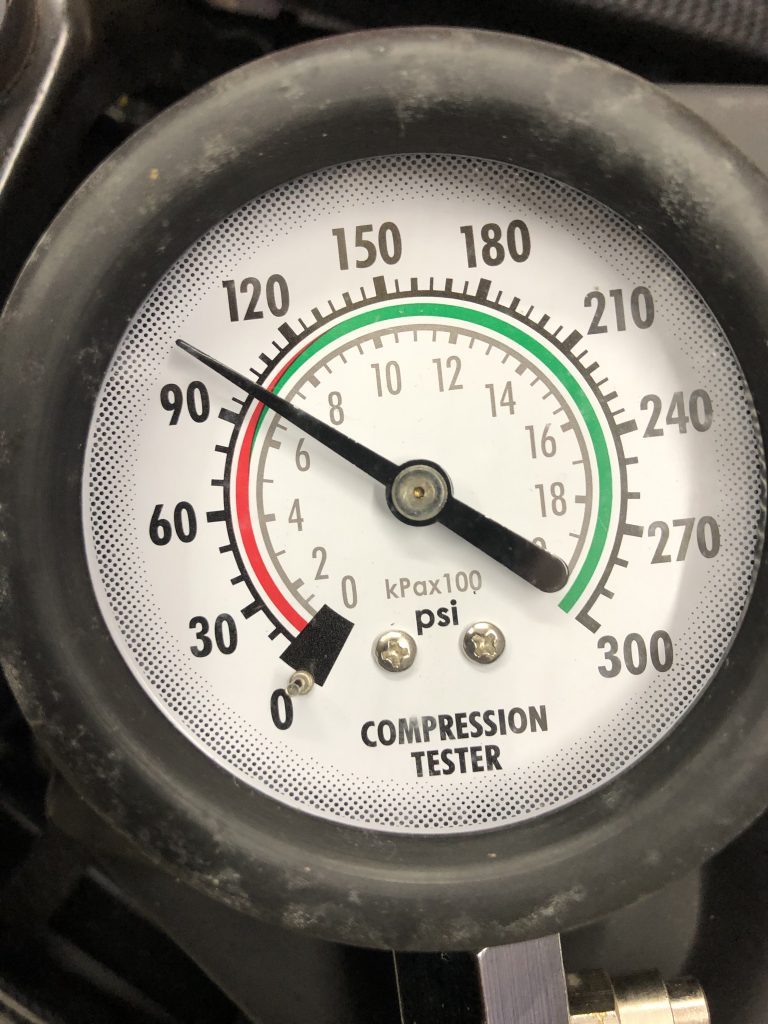

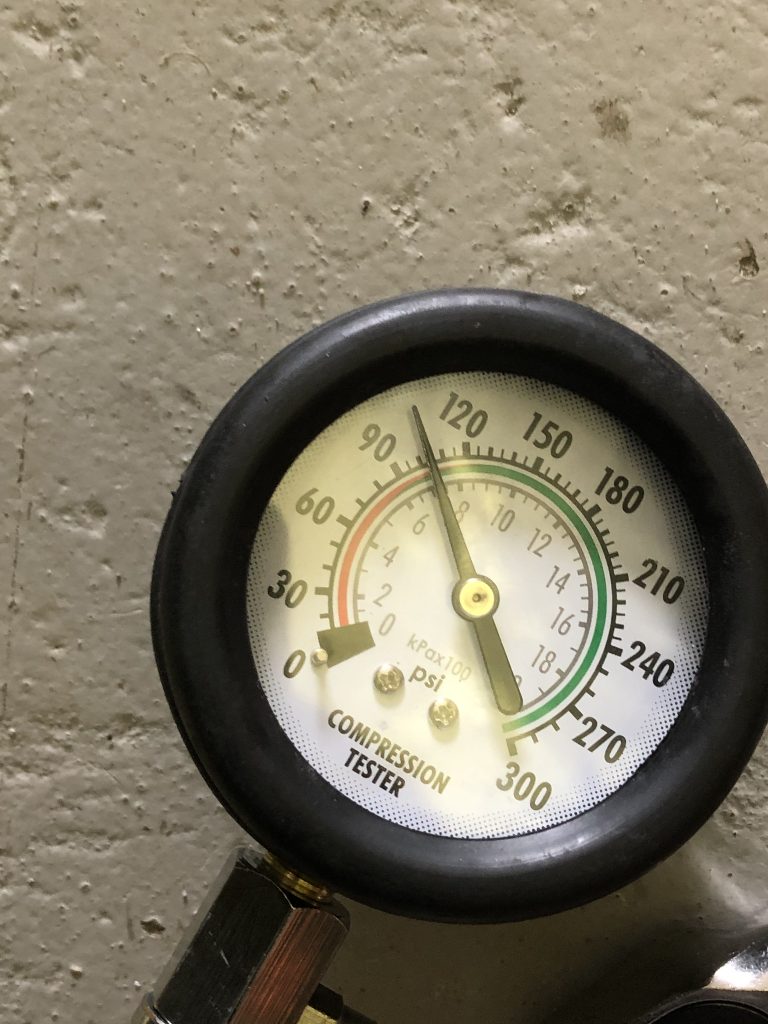

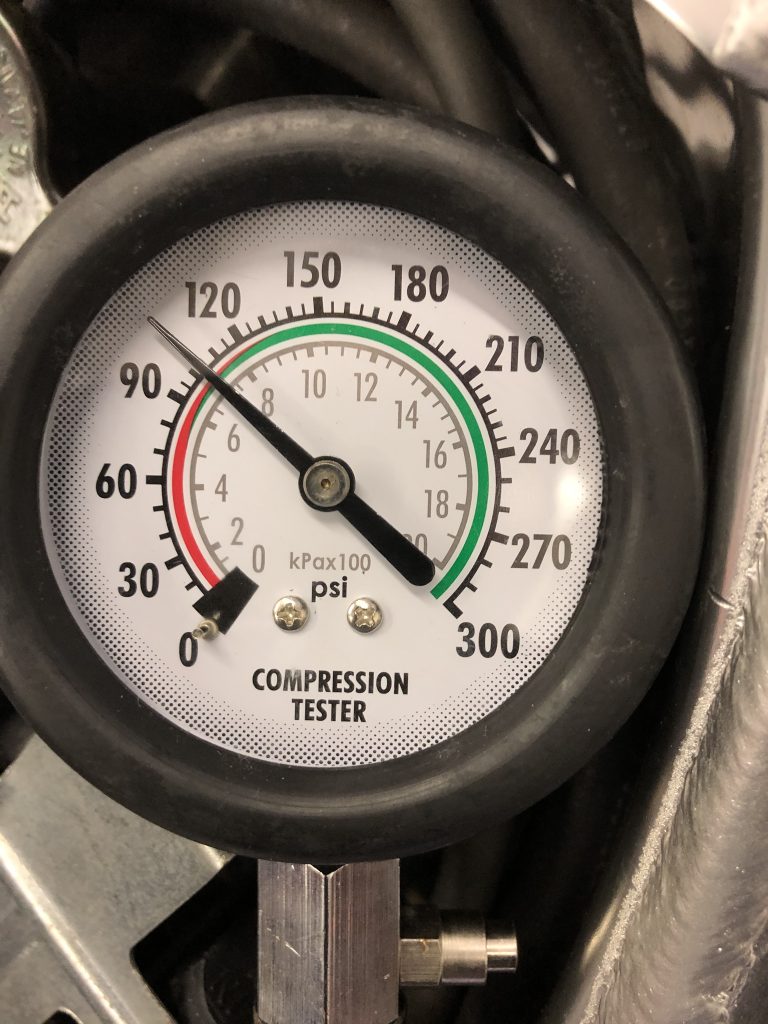

This reworked powerplant featured an overbored Suzuki block fitted with Yoshimura 69mm high compression pistons.

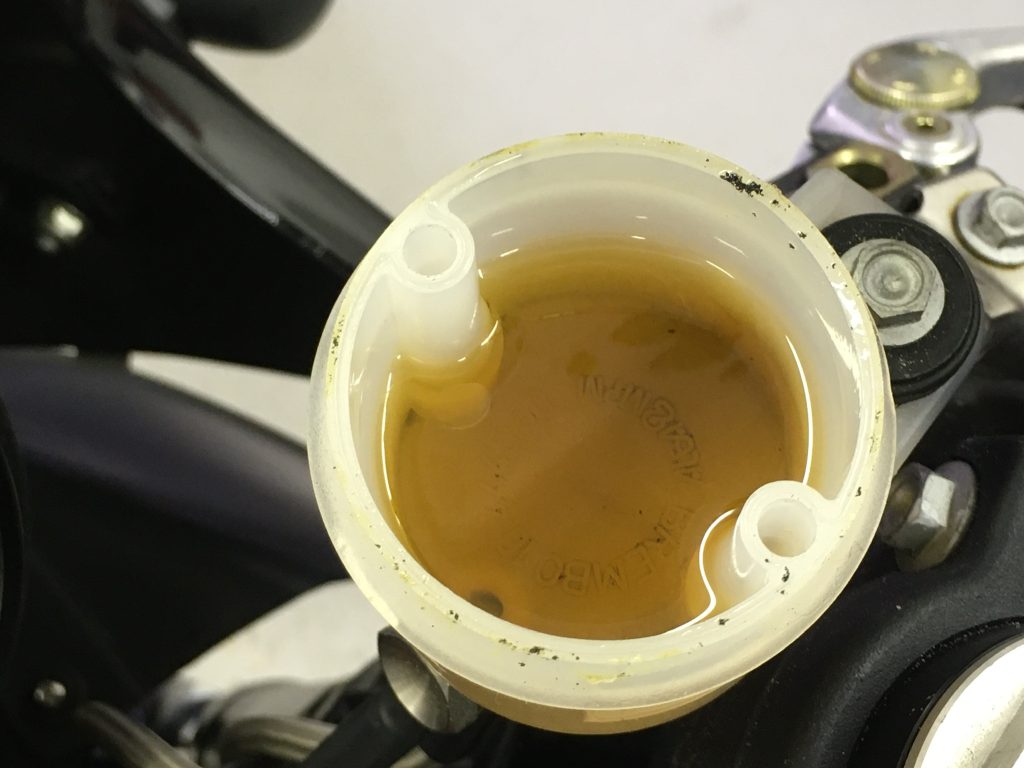

Yoshimura Road and Track camshafts were installed with race valve springs complimented by a Yoshimura ported cylinder head which in turn was fed through a bank of Mikuni 29mm carburettors replacing the standard 26mm items. This upgrade brought power up to 100hp at the engine, a significant increase over the stock 75hp engine output.

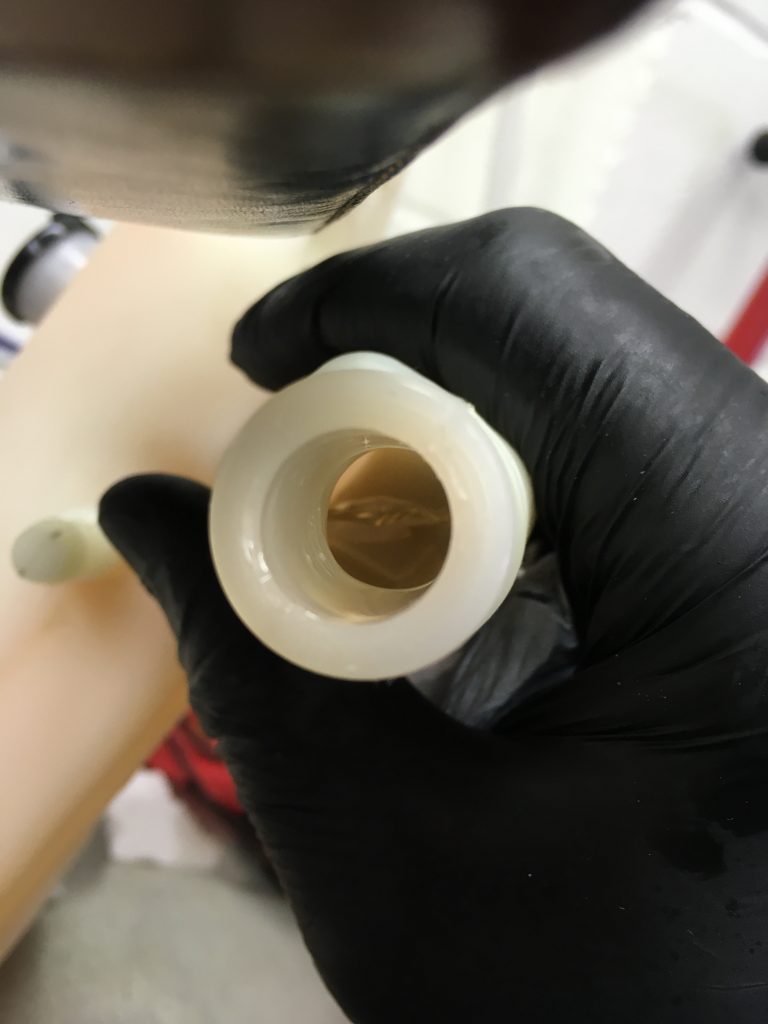

Beautiful details abound, with aircraft grade aluminium featuring everywhere, from die cast footpegs and controls, to the front yokes, rear hub, sprocket, fuel filler cap with enough little machined ‘Bimota’ logos positioned to remind you just which company manufactured this fabulous motorbike, setting a whole new standard for chassis design and exquisite detailing.

The SB2 represented a cut above everything else commercially available, placing Bimota squarely into a boutique niche that it would occupy for decades to come with the Bimota SB2 providing the firm foundations for Massimo Tamburini’s illustrious career while simultaneously raising the bar for the rest of the motorcycle industry.